Case Studies

Success Case - The Benefit of Mine Electrification Simulation

CUSTOMER SUMMARY

The Electric Mining Consortium (EMC) is the world’s leading mining decarbonisation initiative. 4Sight Simulation, in collaboration with a software partner (SimMine), participated in the EMC Simulation Crowd Challenge and was selected from 179 participants to develop a full-scope mine electrification simulation solution.

SimMine partnered with another finalist, SimGenics, to develop an integrated simulation solution of an Australian underground copper mine. This included mining sub-systems interacting over time that enabled stakeholders to fully understand and communicate the value of transitioning from diesel-powered equipment to battery electric-equipment.

CHALLENGES

The following underground mining sub-systems were expected to be impacted by the conversion to battery electric loaders and trucks: (1) Vehicles and mining equipment, (2) Ventilation, (3) Electrical Infrastructure, and (4) Mine Design.

The solution was required to:

• Define the overall mining process and constraints

• Configure/define different equipment types and capabilities

• Define supporting infrastructure

• Constrain and unconstrain any component

The mine electrification simulation had to be able to deliver the following:

• Detailed mine operations with time-varying performance of key metrics

• The evolution of the mine shape/design over time

• Timeframes should run from operational scheduling to life-of-mine planning

• Model fidelity should vary depending on the simulation timeframe

• Incorporate and/or compute an energy cost signal to optimise mining operations inclusive of this signal

• Forecast probabilistic energy requirements sufficient to estimate reserve power system capacity requirements

• The energy requirements of an electrical system, inclusive of power quality considerations

• Asset degradation with electric assets over short and long-term timescales, incorporating these effects to heighten the fidelity of simulations and optimisations

• Known contingency events affecting power systems operation

SOLUTION

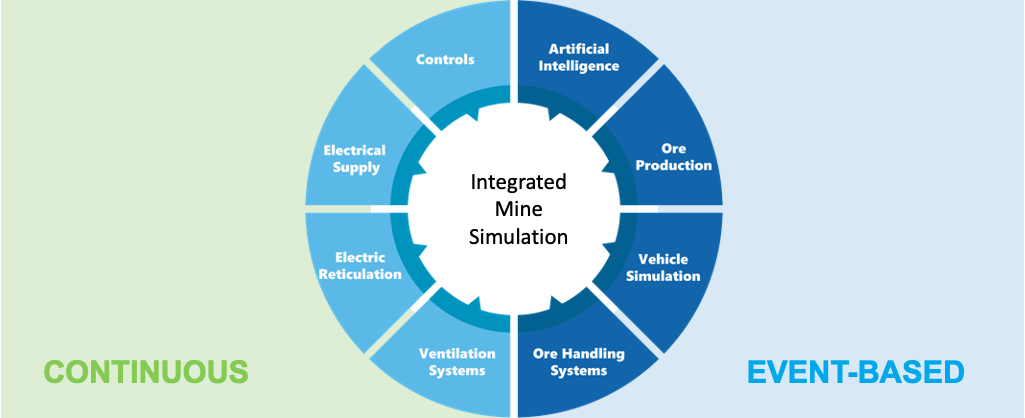

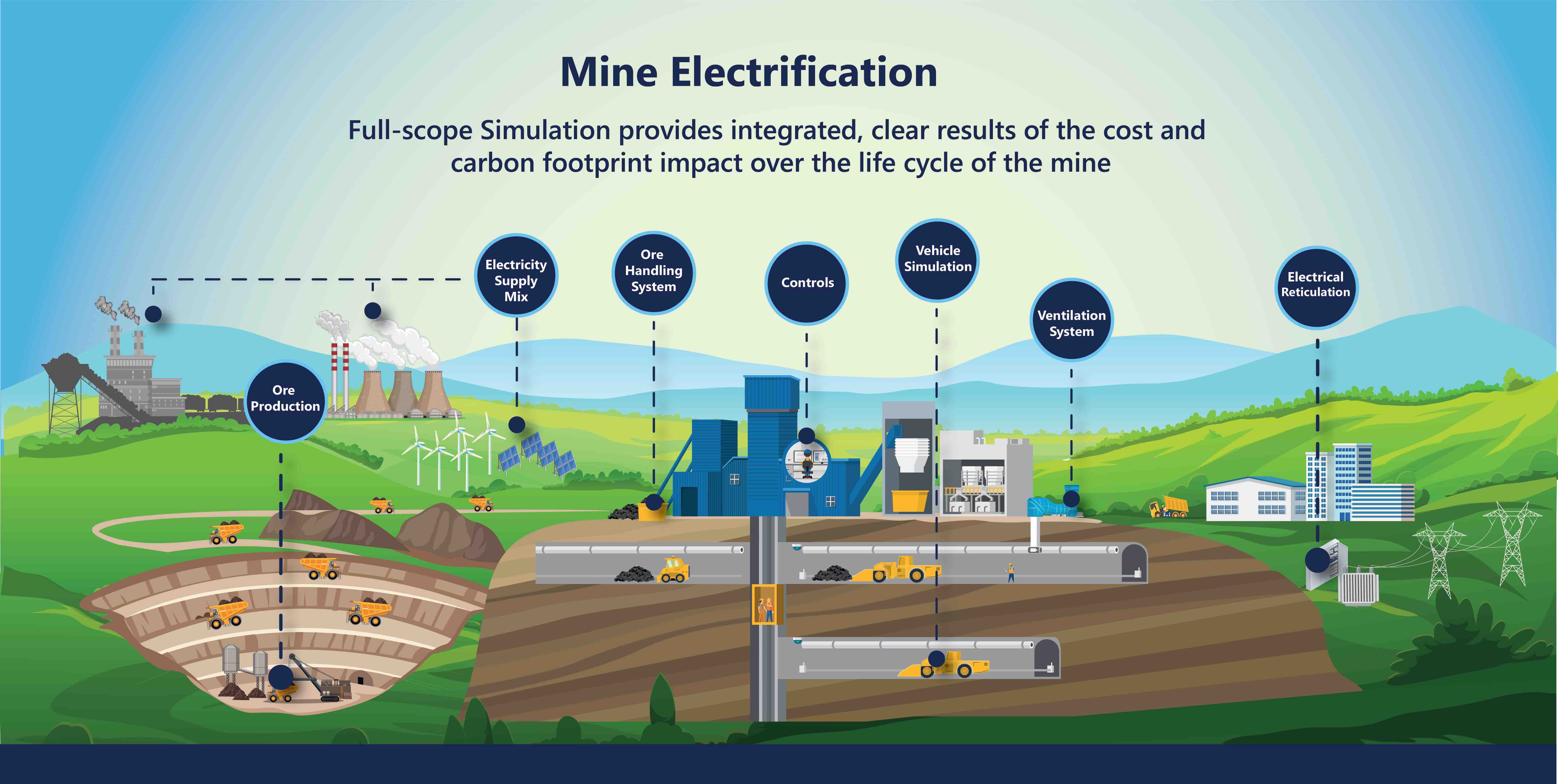

SimMine was integrated with Simgenics’ SimuPACT, and an interface was developed to facilitate cooperation between the two software environments. The figure below schematically describes the elements included in the simulation scope.

The SimMine simulation model includes the mine production schedule and utilises the physical mine layout to model vehicle movement and

ore handling systems. The mine design is imported from Deswik® and automatically populates section attributes, sequences, and dependencies. The model considers the real-world dynamic nature of the Development and Stoping system as well as the infrastructure and backfilling.

The electrical reticulation system is simulated using a high-fidelity electrical network solver being trailed and tested on power plant simulators.

Simulated equipment includes all busses, transformers, transmission lines, battery chargers and all motors for ventilation fans, crushers or loads. The electrical network is ultimately connected to the grid or any alternative power source. The integrated solution allows for a full-scope mine electrification simulation, as illustrated in the below:

BENEFITS & OUTCOME

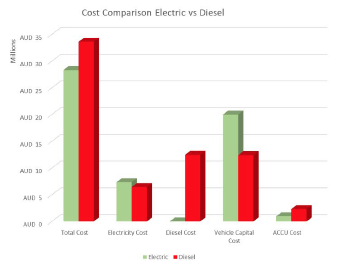

There were many scenarios and trade-offs evaluated, and all results produced the following to evaluate the mine electrification objectives:

• Day-to-day development and production costs of Diesel vs Hybrid vs Electric for LOM

• Day-to-day Scope 1 and 2 emissions for Diesel vs Hybrid vs Electric for LOM

Since all running hours and utilisation of all vehicles are calculated on a day-to-day basis over the LOM, it allows in-time comparison of the costs associated with emissions (carbon taxes/credits) as well as development and production costs for a diesel/hybrid/electric version (or combination thereof) of the mine.

This allows detailed cost calculation to compare the financial feasibility of electrifying a mine or offsetting emissions via Carbon Credits, for a certain period of the full LOM. Fixed and running hour costs for all vehicles are essential to simulate the above costs accurately.