Manufacturing Execution System (MES)

TIMELY, RELEVANT AND SHAREABLE INFORMATION

How do you effectively collect, manage and leverage the vast amount of data within your organisation? The key is an efficient Manufacturing Execution System (MES).

Based on the ISA-S95 framework, our MES implementation delivers efficient data management, operational intelligence via rich visualisation and analytics, and improved production execution— enabling process manufacturers to quickly identify and resolve operational issues.

Bring together the power of data to operate your plant more efficient, with advanced visualisation software that helps production, quality and process engineers remedy and avoid events that limit production profitability.

Enhance Plant Production with MES Solutions

MES - THE POWER OF ONE PLATFORM

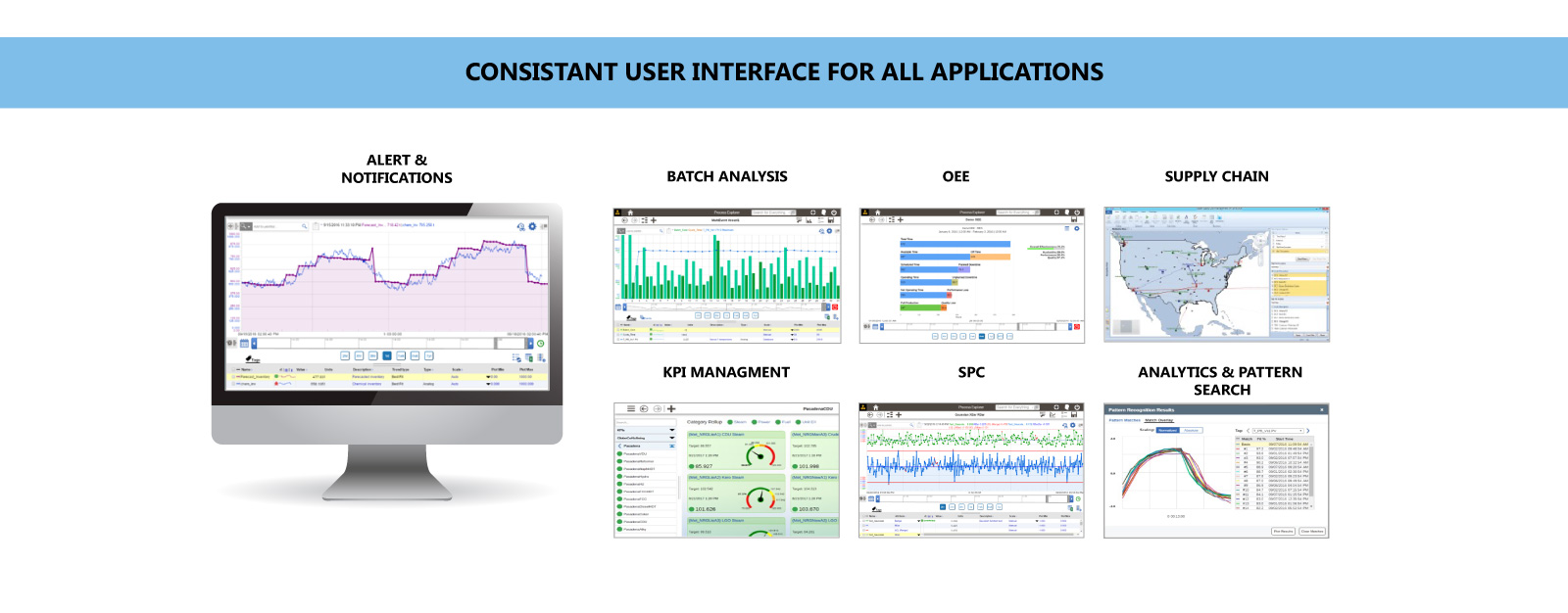

Unparalleled visualisation and analytics in a single, real-time environment

Bring together the power of data to operate your plant more efficiently with advanced visualisation software that helps production, quality and process engineers remedy and avoid events that limit production profitability.

BENEFITS

- Discover the origin of production losses

- Reduce time to identify problems

- Improve product quality & asset utilisation

- Identify opportunities for improving product quality, yield, throughput & safety

- Monitor and Share your most important KPIs

- Insight into Equipment Availability, Performance and Quality

DIGITAL TRANSFORMATION IN MINING OPERATIONS

Digitalisation opens up new ways to increase productivity and achieve operational excellence. Our MES solutions provide comprehensive transparency along the entire value chain.

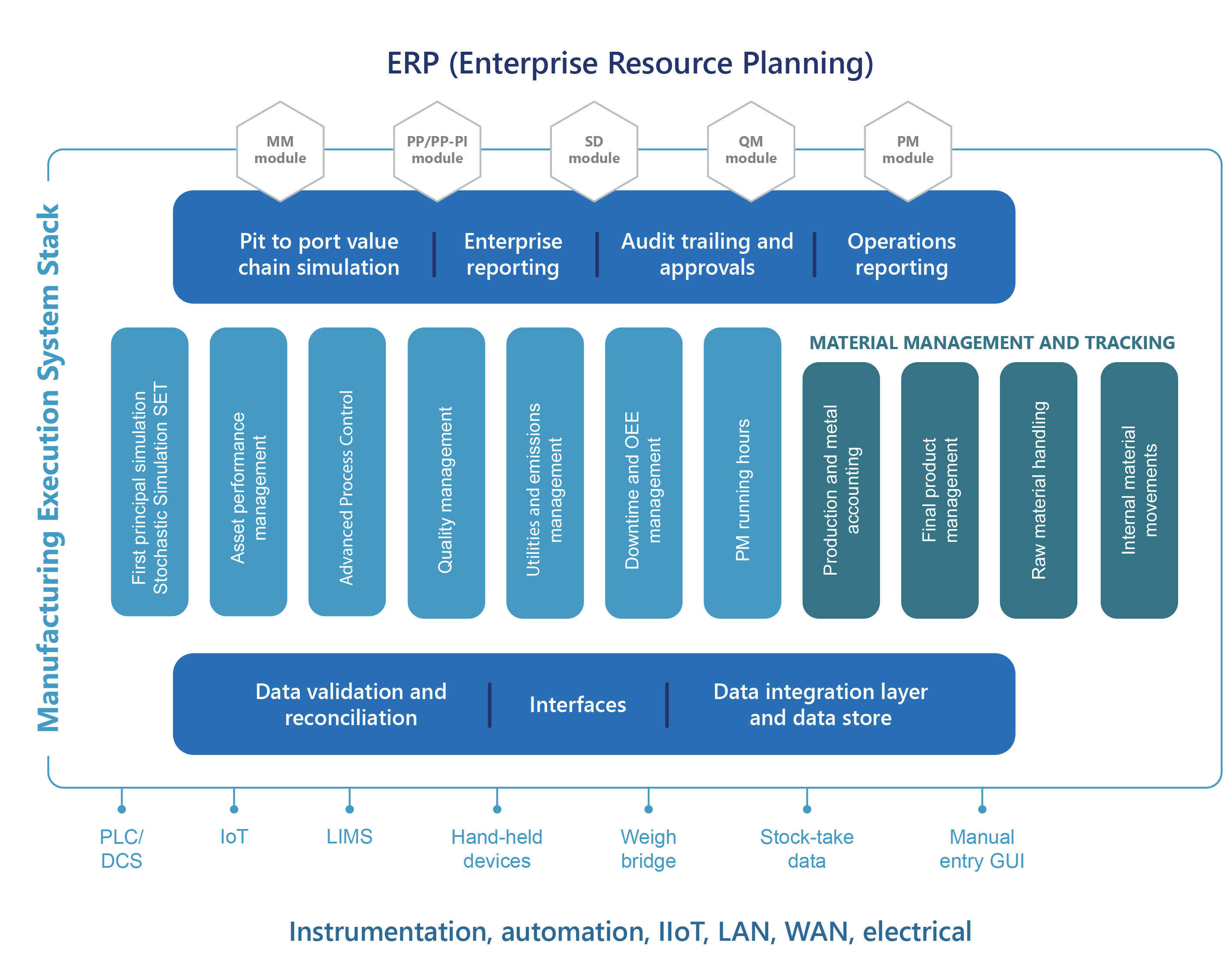

MES SYSTEM STACK

4SIGHT MES EMPOWER MINES THROUGHOUT THE ORGANISATION