Simulation Modelling

What is Simulation Modelling?

Simulation modelling solves real-world problems, safely and efficiently. It provides an important method of analysis which is verifiable and can be translated into the real world. Across industries and disciplines, simulation modelling provides valuable solutions and clear insights into complex systems. Simulation enables experimentation on a valid digital representation of a system. Unlike physical modelling, such as making a scale copy of a building, simulation modelling is computer-based and uses algorithms and equations. Simulation software provides a dynamic environment for the analysis of computer models while they are running, including animation in 3D.

4Sight Asset Simulation specialises in stochastic (random) dynamic (through time) simulation on a systems level. 4Sight Asset Simulation selects the type of simulation type most suited to your requirements to obtain a cost-effective and appropriate solution. Therefore, it could be as simple as a deterministic static calculation (such as Excel or linear programming) or as complicated as stochastics dynamic model with both discrete and continuous elements (such as Simio or SimMine).

When to use Simulation Modelling?

Simulation modelling, especially stochastic dynamic modelling, isn’t always the solution to a problem. It is, however, instrumental in the following cases:

- A Large or Complex System: Reduce the risk of making a poor decision when implementing change by using an objective analysis of accurate behaviour predictions.

- An Expensive or Risky Environment: Save money and reduce risk by testing ideas, first, in a ‘safe’ situation that precisely simulates real-life operations and reactions to change.

- Dynamic Process Variability: Capture the dynamic aspects of a system that impact on its overall performance, including the way that various components interact.

- Incomplete Data Available: Identify missing data, determine the system’s sensitivity to unknowns and explore alternatives when the original model lacks in any way. This approach is especially useful for greenfield projects with uncertain operating conditions.

Why use Simulation?

Simulation modelling is most often used as part of a feasibility study to evaluate the design before implementing. Simulation modelling is also useful to increase throughput and/or reduce Opex of operations without significant capital expenditure.

Simulation modelling assists an organisation to:

- Improve decision making by allowing the inputs and system interaction to influence the final decision

- Identify bottlenecks, with 4Sight Asset Simulation’s bottleneck identifier, we not only identify the current bottleneck but show the subsequent bottlenecks and when they will be reached.

- Create “what if…” scenarios without the risk of testing them in real life, running them over weeks or months, scenarios are executed in hours. The model allows for multiple scenarios and sensitivities. The scenarios allow the organisation to save on capital expenditure (Capex) by testing before implementing.

- Optimise processes by finding the most efficient and effective processes, testing the influence on the system and evaluating results. An optimised organisation reduces operational expenditure and increases throughput.

- Remove the Hippo (Highest paid persons opinion) – Simulation allows decisions to be made based on information rather than opinion, this creates a space where opinions and gutfeel have no place and a neutral space for everyone to interact.

- Quantify the effect of variation - working on averages often gives a false picture of reality, an organisation then adds in factors to compensate. These additional design factors, however, have a financial implication. Simulation modelling allows for accurate accounting of the effect of variation on the system allowing.

- Forecast – Forecast your production and set realistic targets that meet stakeholder expectations.

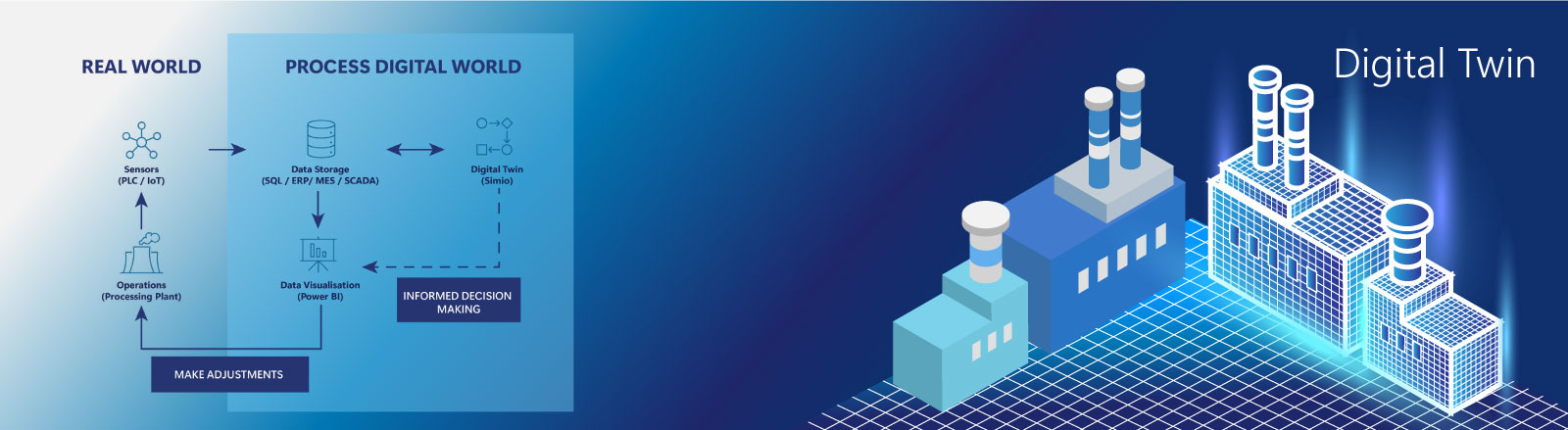

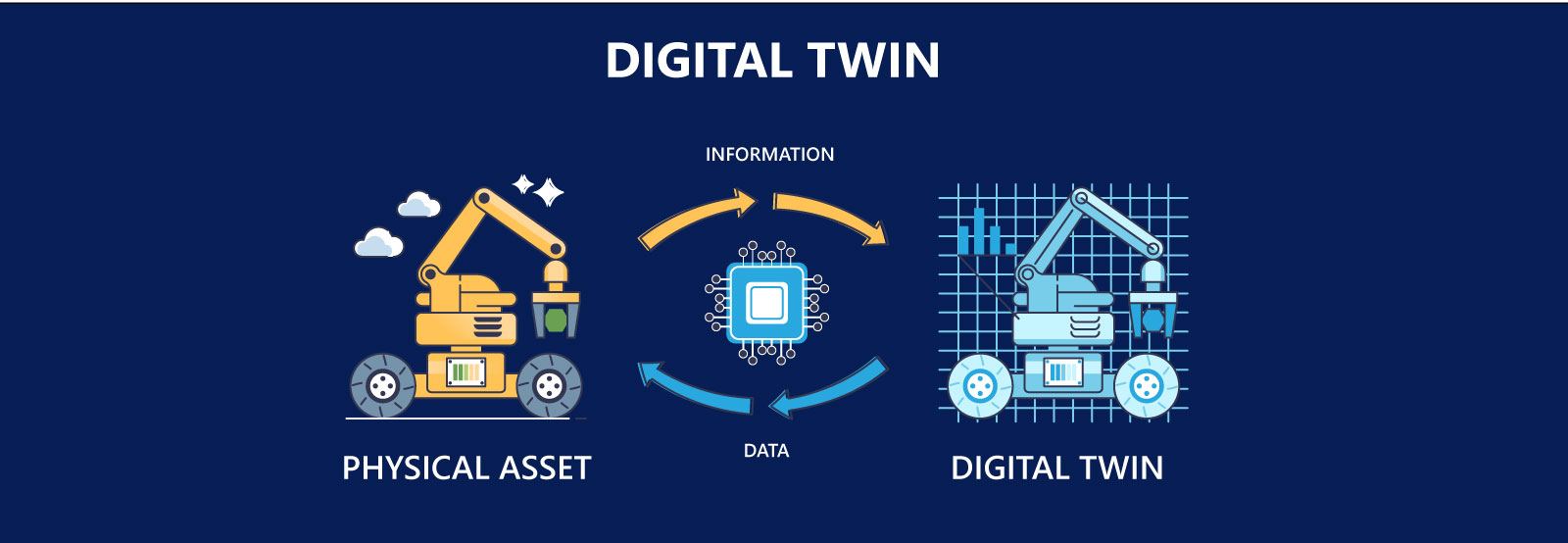

Process Digital Twin & Simulation

The simulation industry has evolved from one of simulation projects to digital twins of operations and value chains. These process digital twins (DTs) are connected to your information system and change and grow with your organisation. Process DTs allow organisations to conduct feasibility studies on new investment before committing capital. DTs can reduce the cycle time of feasibilities from months to days. We often have clients who don’t have the information systems available to support process DTs, lack of information doesn’t mean that you can’t gain from a DT (although it is strictly speaking can’t be called a DT). In this case, we construct a simulation model intending to become a process DT, linking up the information

as it becomes available. The simulation model then also guides the organisation on the type of information to gather to inform decision making. The model will still have the same advantages, but information gathering will require more effort and time.

The Process Digital Twin allows you to:

Simulation modelling, a way to create an exact mirror image of your business processes. This mirror image, or “digital twin”, behaves the same way as the current system, but it all takes place within a virtual environment.

Software Sales & Training

Giving your employees the tools and skills they need