Blog - Operational Technologies

Beyond the Buzzwords 5 Surprising Realities of AI-Powered Advanced Process Control (APC)

it bridges the gap between data and decision-making. It gives engineers the predictive insight to act before deviations occur, helping operations run closer to their true potential - safely, efficiently, and consistently"

Introduction: The Unseen AI Conductor of Modern Industry

Imagine conducting an orchestra where every musician is playing

a slightly different tune, and every instrument’s pitch changes with the temperature in the room. Now imagine there are ten thousand musicians. This is the daily reality for operators running a modern industrial facility such as a chemical plant or oil refinery. The sheer complexity of interacting variables - temperatures, pressures, flow rates, and compositions - is beyond human capacity to manage optimally. This is where AI-powered Advanced Process Control (APC) steps in. It’s not just automation - it’s a sophisticated layer of intelligence that acts like an expert conductor for the industrial orchestra. By combining advanced mathematics with machine learning and artificial intelligence, APC continuously analyses thousands of variables, learns from process behavior, and makes subtle, predictive adjustments to keep everything in perfect balance. The result? Facilities that run closer to their optimal limits, consume less energy, maintain tighter quality control, and respond faster to change - all while staying safely within operational boundaries. While the term “Advanced Process Control” might sound abstract, its AI evolution has made it one of the most powerful enablers of industrial performance today. Let’s explore five surprising realities of how

AI-enhanced APC is transforming operations across industries.

The Payback is Measured in Months, Not Years

Industrial AI initiatives are often seen as long-term digital investments with uncertain returns. APC challenges that perception entirely. When combined with AI-based modeling and continuous learning, APC projects typically pay for themselves within three to six months. Even in complex scenarios - like optimising a distillation column or reactor - APC delivers measurable ROI far faster than most digital transformation projects. This quick turnaround turns APC from a speculative investment into a high-impact operational strategy. It’s not just a control system - it’s a smart financial tool for extracting hidden value from existing assets using real-time data and AI-driven decision-making.

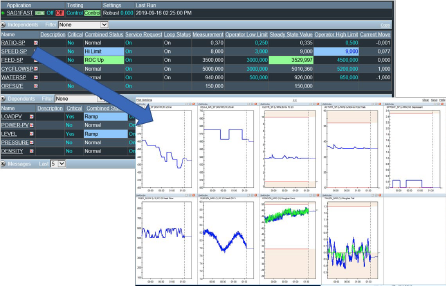

It Creates AI-Driven ‘Digital Senses’ to See the Unseeable

In many industrial processes, the most critical product-quality indicators can’t be measured in real time - they require lab samples and delayed feedback. AI-enabled APC solves this with soft sensors, or inferential models, that act like digital senses for the process. By using machine learning algorithms trained on historical and live data, APC can continuously estimate hard-to-measure variables such as product composition or purity. What used to take hours or days to verify can now be inferred in seconds. In practical terms, that means operators can “see” invisible process changes as they happen and adjust instantly. This AI-driven insight dramatically reduces variation, improves product consistency, and minimises off-spec production - transforming quality control from reactive to predictive.

The Secret Isn’t Just Reaction, It’s AI Prediction

Traditional control systems react to deviations - like a thermostat responding to a temperature change. AI-enhanced APC operates on a higher plane: it predicts what’s about to happen and corrects it before it does. Using dynamic models and predictive AI algorithms, APC forecasts future process behavior and fine-tunes control actions in advance. This forward-looking intelligence helps plants avoid disturbances, reduce variability, and operate safely at optimal performance levels. In batch operations, AI models can predict end-of-batch outcomes early in the run, allowing automatic corrections mid-process. This proactive, predictive capability turns process control into a competitive advantage - maximising profitability without increasing risk.

It’s a Continuous Collaboration Between AI and Human Expertise

While AI and automation are powerful, APC success still depends on people. The system’s intelligence is only as strong as the collaboration between human experts and digital algorithms. Over time, process models can drift from real-world behavior due to fouling, calibration shifts, or process modifications - a phenomenon known as model drift. AI now plays a growing role in detecting and compensating for drift automatically, but human insight remains critical for validation and optimisation. This creates a powerful human-AI partnership. Engineers define process objectives and interpret results, while AI continuously learns, adjusts, and maintains peak efficiency. The result is not “automation replacing humans,” but rather AI augmenting human expertise to achieve performance levels previously out of reach.

It’s Expanding Beyond Refineries - Thanks to AI Adaptability Historically,

APC was limited to large, continuous industries like refining and petrochemicals. Today, the integration of AI has changed that completely. Machine learning allows APC systems to handle nonlinear, variable, and batch processes with unprecedented flexibility. This makes AI-driven APC viable across specialty chemicals, food and beverage, pharmaceuticals, pulp and paper, power generation, and even mining. In batch environments, AI models can continuously learn from each run, adjusting recipes and timing in real time to ensure consistent outcomes - despite fluctuating raw materials or operating conditions. AI has, in essence, democratised APC, bringing its benefits to operations of all sizes and levels of complexity.

Conclusion: The Quiet AI Revolution in Manufacturing

AI-powered Advanced Process Control represents a major leap forward in industrial automation. It turns process data into foresight, replaces delay with instant feedback, and transforms reactive control into predictive optimisation. More than a technology, it’s a strategic enabler of the autonomous plant - one that learns, adapts, and improves over time. By blending artificial intelligence with human expertise, APC

allows manufacturers to push the boundaries of efficiency, sustainability, and profitability. Ready to Unlock the Power of AI-Powered APC? If you’re ready to see how AI-driven Advanced Process Control can transform your operations - boosting performance, cutting variability, and delivering measurable ROI - contact 4Sight today.

Our team of APC and AI specialists can help you identify high-impact opportunities, design tailored control strategies, and demonstrate how intelligent automation can unlock the next level of operational excellence. Email us at This email address is being protected from spambots. You need JavaScript enabled to view it.