Blog - Operational Technologies

Optimising Supply Chain Efficiency with AI-Driven Inventory Management

today’s dynamic supply chain landscape.

4Sight Operational Technologies and Simio will be exhibiting at the SAPICs 47th Annual Conference. Discover the Future of Supply Chain Management at SAPICS 2025! Join us June 8-11 at stand S37 for an Exclusive Dual Exhibit Experience, Century City, Cape Town. Click here to learn more...

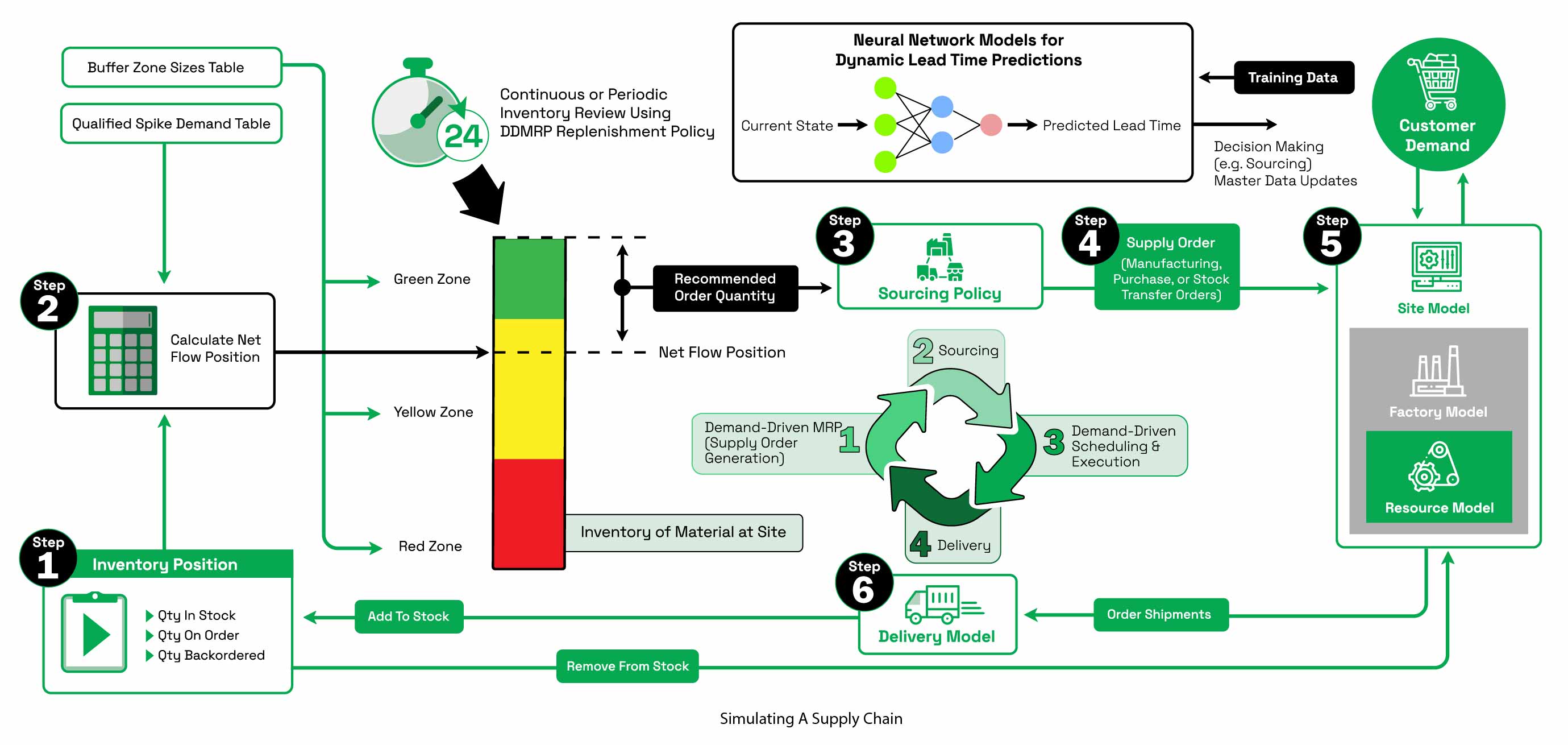

In today’s fast-paced industrial landscape, maintaining an efficient supply chain is more critical than ever. At 4Sight Operational Technologies, we’re proud to lead the charge in transforming inventory management through cutting-edge AI solutions. The below diagram outlines a sophisticated, AI-powered process that integrates real-time data, predictive analytics, and dynamic decision-making to optimise inventory levels and ensure seamless operations. Let’s break down this innovative approach and explore how it can revolutionise your business.

Step 1: Establishing Inventory Position

The process begins with a clear assessment of the inventory position. This involves calculating the quantity on stock, on order, and backordered. By establishing a baseline, businesses can gain a comprehensive view of their current material availability. This foundational step sets the stage for accurate planning and ensures that all subsequent decisions are data-driven.

Step 2: Calculating

Net Flow Position Next, we calculate the net flow position by factoring in buffer zone sizes and qualified spike demand tables. These tools help identify potential demand fluctuations and maintain safety stock levels. This step is crucial for anticipating market changes and avoiding stockouts or overstock situations, providing a proactive approach to inventory control.

Step 3: Dynamic Replenishment with Neural Networks

At the heart of our system is a continuous review of inventory using a 24-hour DDMRP (Demand-Driven Material Requirements Planning) replenishment policy. Neural network models predict dynamic lead times based on the current state, offering a significant edge over traditional methods. This AI-driven insight recommends order quantities tailored to real-time conditions, ensuring optimal stock levels and reducing waste.

Step 4: Demand-Driven and Supply-Driven MRP

The process integrates demand-driven and supply-driven MRP generation, creating a feedback loop that refines sourcing policies. This dual approach allows for agile adjustments, whether through manufacturing, stock transfers, or purchase orders. By aligning supply with demand, businesses can minimise delays and enhance operational efficiency.

Step 5: Supply Order Execution

Once the sourcing policy is set, supply orders are executed based on decision-making algorithms that update master data. This step leverages site and factory models to ensure that production and resource allocation align with demand forecasts, streamlining the transition from planning to action.

Step 6: Delivery and Customer Satisfaction

The final step involves the delivery model, which manages order shipments to meet customer demand. By closing the loop with real-time data, this process ensures timely deliveries and maintains high customer satisfaction levels. The integration of a resource model further optimises factory operations, creating a cohesive supply chain ecosystem.

The 4Sight Advantage

At 4Sight Operational Technologies, we believe that AI is the future of supply chain management. This diagram represents a holistic system where every step is interconnected, driven by data and enhanced by predictive analytics. By adopting such a strategy, businesses can reduce costs, improve responsiveness, and stay competitive in a dynamic market. As of May 16, 2025, this approach is at the forefront of operational technology, and we’re excited to see its impact grow. If you’re interested in implementing a similar system, reach out to 4Sight Operational Technologies to explore how our expertise can elevate your supply chain performance. Together, we can build a more resilient and efficient future.