Blog - Operational Technologies

Why Every Mining and Industrial Engineering Team Needs an AI Roadmap - Not jus an AI tool

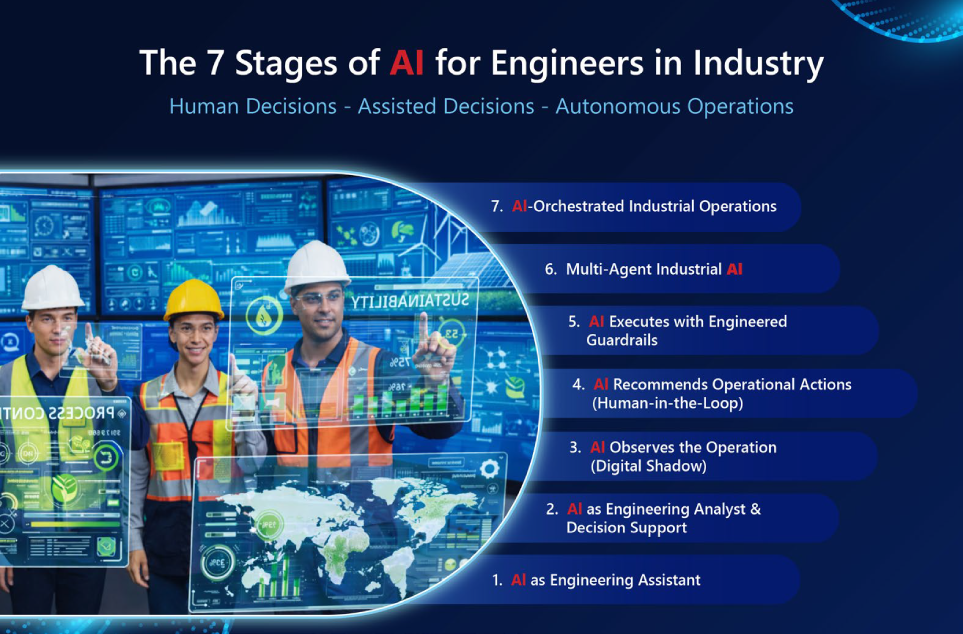

Artificial Intelligence is no longer a future concept for industry—it is already embedded in how engineers analyse data, understand operations, and make decisions. Yet many industrial organisations struggle with the same question: Where do we realistically start with AI, and how far should we go? At 4Sight Operational Technologies, we see successful AI adoption not as a single transformation project, but as a progressive journey. One that moves deliberately from human-led decision making to assisted intelligence, and eventually toward autonomous, optimised operations. This journey can be clearly described through seven distinct stages of AI maturity for engineers in industry.

Stage 1: AI as an Engineering Assistant

The first stage introduces AI as a non-operational assistant. At this level, AI helps engineers interpret information, summarise documentation, and access institutional knowledge faster—but it has no authority over the process. Typical use cases include summarising operating procedures, explaining control logic, interpreting alarms and event logs, and generating shift handover notes. The value here is speed and clarity, not control. Importantly, this stage builds AI literacy while enforcing strict guardrails around safety and operational risk.

Stage 2: AI as an Engineering Analyst and Decision Support

In Stage 2, AI begins analysing operational technology (OT) data to explain why systems behave the way they do. Engineers remain fully in control, but decisions are now supported by deeper, faster insights. Here we see historian-based root cause analysis, production constraint identification, energy benchmarking, and quality deviation investigation. This is often the highest-value entry point for industry, as it directly addresses hidden losses, inefficiencies, and instability—without introducing autonomy.

Stage 3: AI Observes the Operation (Digital Shadow)

At this stage, AI continuously observes processes, assets, and energy usage, forming a digital shadow of the operation. It does not act, but it watches relentlessly. AI monitors operating envelopes, detects early deviations, tracks asset health, and identifies alarm flood patterns. Engineers define what “normal” looks like, what matters, and when escalation is required. Trust is built through consistency, accuracy, and explainability.

Stage 4: AI Recommends Operational Actions (Human-in-the-Loop)

Now AI begins to recommend actions—but humans still decide. These recommendations are explainable, contextual, and aligned with engineering logic. Examples include guidance to stabilise a process, prioritise maintenance, shift energy loads to avoid peak tariffs, or adjust production rates. This stage represents peak decision value, where AI connects insight to action while respecting operational accountability.

Stage 5: AI Executes Within Engineered Guardrails

Stage 5 introduces controlled autonomy. AI is allowed to execute actions—but only within clearly defined safety, control, and operating limits. Closed-loop optimisation, automated setpoint tuning, energy optimisation routines, and condition-based maintenance triggers become possible. Governance is critical here: rollback mechanisms, KPIs, and approval frameworks must be engineered just as carefully as the AI models themselves.

Stage 6: Multi-Agent Industrial AI

As complexity increases, multiple AI agents begin coordinating across domains. One agent may optimise production, another energy, another maintenance—each negotiating trade-offs in real time. This stage enables site-wide optimisation, balancing throughput, cost, reliability, and sustainability. Architectural design and cross-domain governance become essential to avoid conflicting objectives.

Stage 7: AI-Orchestrated Industrial Operations

The final stage represents enterprise-level orchestration. AI coordinates across people, agents, OT and IT systems, planning tools, and supply chains. This enables mine-to-mill optimisation, carbon-aware operations, integrated planning and execution, and orchestration of executive-level decisions. At this level, AI becomes part of the operating model itself—not just a tool.

A Journey, Not a Jump

The key lesson for engineers is this: AI maturity is not about skipping stages. Each stage builds trust, capability, and governance. Organisations that rush toward autonomy without mastering decision support and observability often fail to realise value or worse, introduce risk. The most successful industrial AI programs are engineered with the same discipline as control systems: incremental, explainable, and grounded in operational reality.

AI maturity isn’t about how advanced your tools are; it’s about how well the journey is engineered. 4Sight partners with industrial and mining teams to design AI roadmaps that build trust, governance, and real operational value, stage by stage. Email This email address is being protected from spambots. You need JavaScript enabled to view it. to learn more!