Case Studies - Operational Technologies

Room and Pillar Mine Optimisation Model

Ore Handling Model

Primary Objective

The primary objective of the ore handling simulation model was to determine the individual mining section’s throughput capacity given the equipment constraints and alternative operating parameters.

Secondary Objective

Secondly, to test the capacities of the trunk and decline conveyors.

Personal Logistics Model

Primary Objective

The objective of the personnel logistics model was to establish how different shift hours affect the average available personnel face-time for different scenarios.

Secondary Objective

The secondary objective was to determine how the hours available in a shift is allocated to the different elements that constitutes a full working day.

Approach

The simulation model was constructed in detail to understand the variability of the rock arrival profile on strike and subsequently on the main decline conveyor.

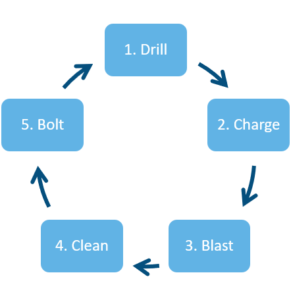

Figure 1: The Mining Cycle

- Mining cycle for the room and pillar method

- LHD loading and transportation to tip(s)

- Ground support activities using Bolters

- Operating schedules, feed rates

- Conveyor speeds/movement rate

- Strike conveyors merging onto Decline conveyor

- Maintenance strategy/intervals and durations

- Availabilities, failures (MTBF, MTTR)

- Personnel chairlift to a designated level and working areas

- Transportation to and from Work areas

- Walking, queuing at chairlift stations

- Personnel delay for shift durations

Results

Several scenarios with different equipment configurations were evaluated for both the current shift schedule (10-hour shift) as well as the new proposed shift schedule (12-hour shift).

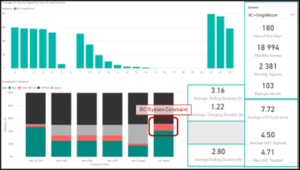

Figure 2: Room And Pillar Section Dashboard – Current Shift Operations

Figure 3: Room And Pillar Section Dashboard – Proposed Shift Operations

The following conclusions below were made based on the results of the simulation study.

Current Shift Operations

- The required monthly target can be reached with the current configuration given that the operational constraints are lifted from the mining cycle operations

- Combined section throughput can be increased by aligning the belt feeder capacities with the strike belt capacities

New Shift Operations

- The proposed shift operations allowed for additional capacity and throughput

- Individual sections can achieve more than the required throughput, given the introduction of additional Bolters and/or double-boom drilling operations

Personnel Logistics

- For the current shift schedule, face-time will decrease to 7.7 hours during later stages for the Life of Mine (LOM)

- With the new proposed shift schedule, face-time will still decrease but only to 8.5 hours during later stages for the Life of Mine (LOM)