Case Studies - Operational Technologies

Using simulation to make data-informed logistics decisions

Customer Summary

Anglo Gold Ashanti (AGA) needed assistance to determine the logistical requirements to cross-tram rock, personnel and materials between Tau Tona and the Mponeng SS1 Shaft on 120L. 4Sight | OT | Asset Simulation (formally Simulation Engineering Technologies), developed a simulation model introducing the proposed Tau Tona link to the existing Mponeng Simio® simulation model to assist AGA in making data-informed decisions regarding the feasibility.

Approach

A simulation model was developed using market-leading discrete event simulation software. The following operations are included in the simulation:

- Rock tramming from Tau Tona to Mponeng

- Current operations

- Double-header loco operations

- Direct, relay and shunting operations

- Detail level haulage for personnel and materials between Mponeng and Tau Tona

- Current hoisting operations

- Proposed revised personnel hoisting

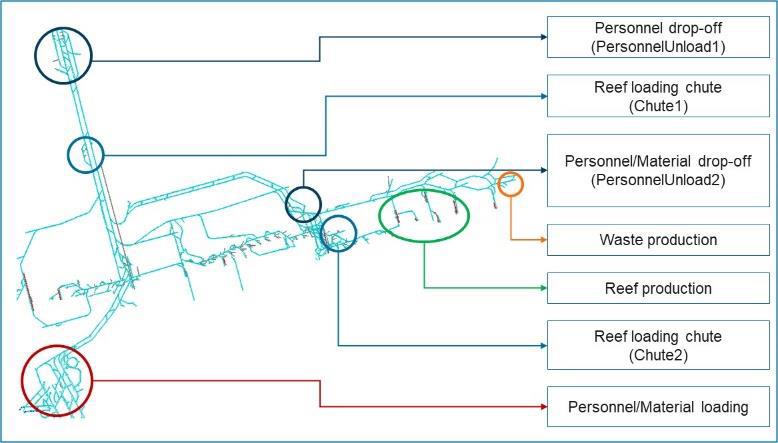

The various operations and areas evaluated during the study are shown below.

Solution

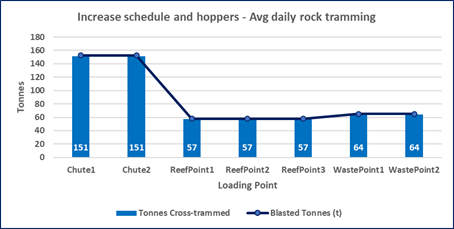

Multiple scenarios were tested to determine the best configuration for the rock tramming operation to achieve its targets.

Some tested scenarios include:

- Revised operations

- Hopper count sensitivity analysis

- Fleet size analysis

- Loco speed sensitivity analysis and more

Benefits and Outcomes

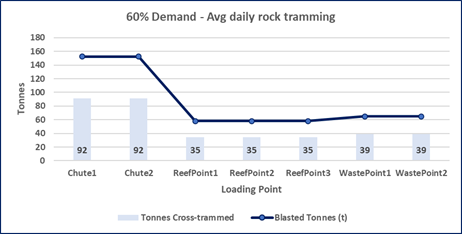

The initial scenarios evaluated the current operations, and the fleet capacity as is. This included iterations incrementing the proposed production to determine the system capacity if nothing changed. The simulation results indicated that the current operations would only be able to achieve 60% of the proposed production plan.

Fleet increment scenarios were tested to establish if the planned monthly tonnes would be met. The scenarios tested include:

- Loco speed scenarios

- Wagons per span scenarios

- Loco fleet scenarios

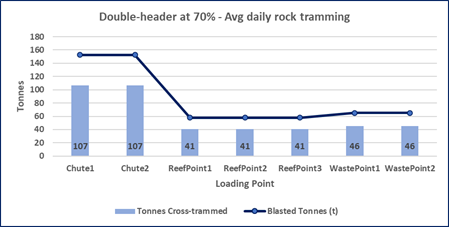

None of these scenarios could effectively increase the throughput to meet the monthly planned tonnes. Further initiatives tested introduced dedicated doubleheader locos for cross tramming purposes. These loco sets would comprise two spans combined to increase capacity per trip. This, however, had a reduced throughput compared to the current operations and could only achieve 50% of the planned production, as the inefficiencies waiting for increased loads reduced the flexibility in the system to tram the required tonnes.

A large portion of the tramming shift was currently being utilised for moving personnel to their respective working areas. The option to remove personnel hoisting at the SS1 was tested to increase the scheduled rock tramming time. This additional hoisting time allowed the double-header system to achieve 70% of the planned production tonnes.

The current operations provided greater flexibility and more throughput, when compared to the double-header system. The increased tramming operations were also tested when applied to current operations, allowing for 95% of the planned tonnes to be trammed with the existing resources.

This solution allowed the mine to achieve its tramming targets without having to invest in upgrading rail infrastructure for larger loco sets.

Click here to learn more about Anglo Gold Ashanti.