Offerings

Advanced Process Control - optimising processes in industrial process control systems

Increase Company Profit Through Optimising Processes

ACHIEVE PRODUCTION EXCELLENCE WITH INDUSTRY-LEADING APC TECHNOLOGY

4Sight’s AI-driven Advanced Process Control solutions bring new intelligence to industrial operations, enabling businesses to optimise their processes in real-time. Integrating advanced AI algorithms with traditional control systems, we help industries improve efficiency, reduce waste, and enhance production output. Our solutions are designed to automatically adapt to dynamic conditions, ensuring consistent performance while lowering operational costs. With 4Sight’s expertise, businesses can achieve greater precision, minimise downtime, and meet their production targets with cutting-edge, data-driven technologies.

Bring together the power of data to operate your plant more efficiently, with advanced control software that helps production, quality and process engineers remedy and avoid events that limit production profitability.

4Sight’s APC expertise has been at the forefront of Multivariable Model Predictive Control (MPC) projects since 2000, delivering numerous benefit-driven solutions across the globe in the Mining, Metals, and Minerals sectors and the Petrochemical industry. As early adopters of APC, the Petrochemical sector provided 4Sight with invaluable knowledge and experience, which we have successfully applied to the Mining sector, achieving significant results.

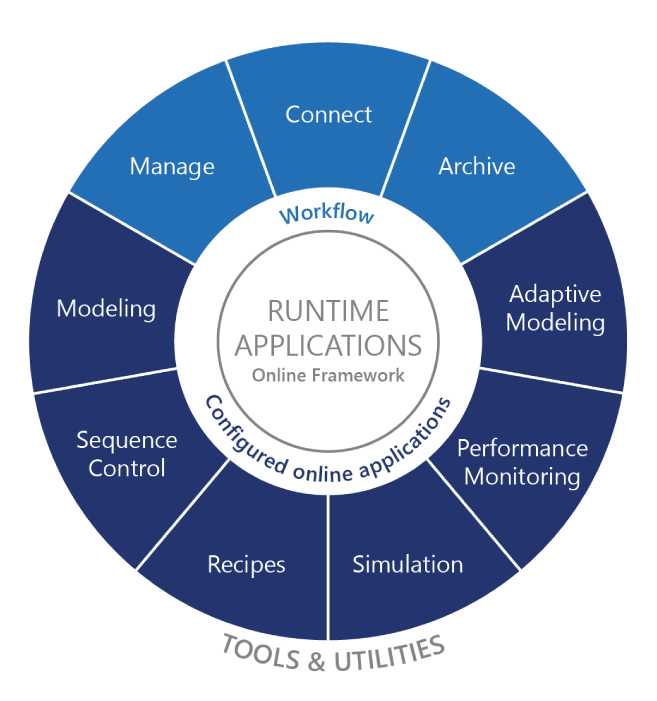

AspenTech Advanced Process Control provides a full set of integrated features for developing, deploying, and maintaining advanced control applications.

Advanced Process Control refers to a technology that is implemented within industrial process control systems, to address specific performance or economic improvement opportunities in the process.

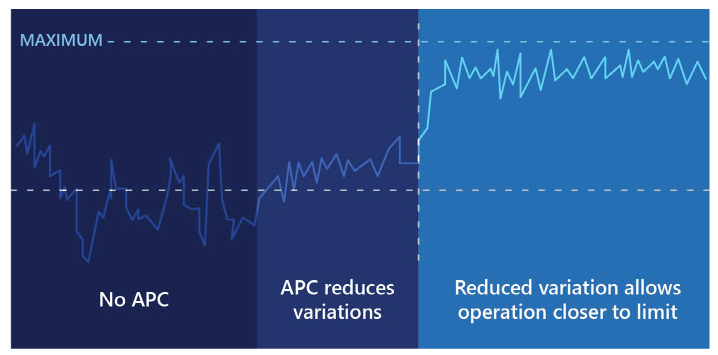

Model Predictive Control (MPC) is the key component of an APC system, that enables optimal process operation, resulting in increased productivity. MPC achieves this by predictive control using dynamic process models, which is proven to increase throughput, save energy, and reduce quality giveaway. As the MPC control strategies vary, our experienced APC engineers work closely with experts alongside our customers to ensure successful and seamless implementation.

- Reduced process variability

- Push profitable constraints

- Reduce product quality variability

AspenTech Advanced Process Control enables companies to increase throughput, improve product quality, reduce energy and raw material usage, and increase overall operational efficiency while keeping the process between safe limits of reliable operation. Additional benefits include standardisation of processes and consistent use of best practices, ensuring higher operational stability and reduced maintenance requirements, therefore sustaining long-term value.

SOLUTIONS ADDRESSING INDUSTRY CHALLENGES

- Adapt and Optimise Simultaneously - Improve ROI with rapid controller deployment, continuous model improvement and simplified work flows to enable more engineers to implement and maintain APC systems.

- Simplify Tuning and Optimisation - Streamline controller tuning with a step-by-step configuration wizard to directly specify objectives.

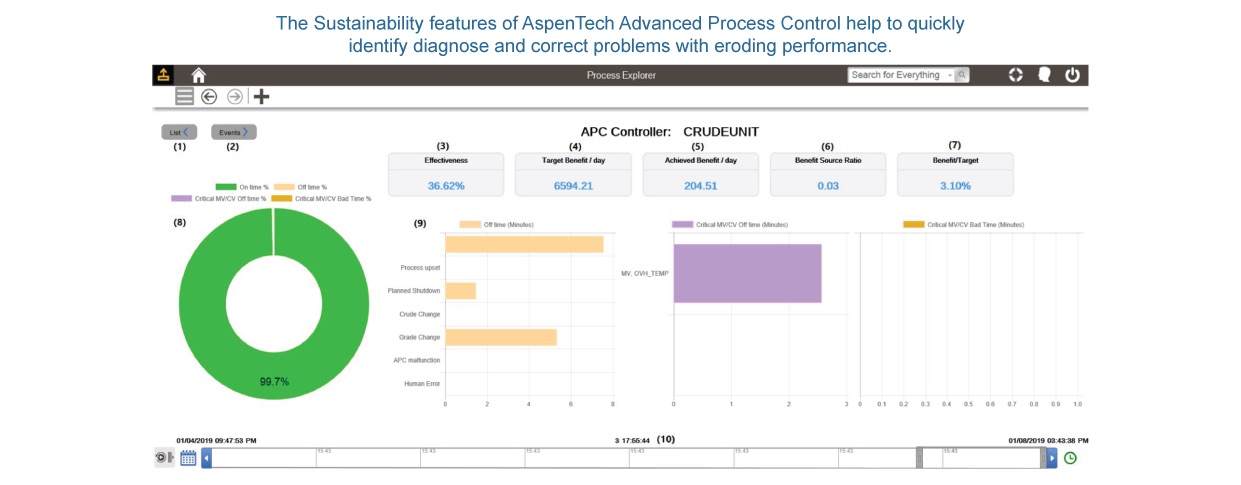

- Monitor with Real-Time Diagnostics - Visualise, analyse, monitor and access real-time controller KPIs to gain key insights into controller performance.

SOLUTION ELEMENTS

The benefits of one integrated solution for optimising linear and non-linear processes:

- Adapt and Optimise Simultaneously - Improve ROI with rapid controller deployment, continuous model improvement and simplified workflows to enable more engineers.

- Simplify Tuning & Optimisation -Streamline controller tuning with a step-by-step configuration wizard to directly specify objectives.

- Improve Performance With Robust Control - Increase controller up-time by making controllers more resilient to model quality issues and process disturbances.

- Monitor With Real-Time Diagnostics Visualise, analyse, monitor and access real-time controller KPIs to gain key insights into controller performance.

The AspenTech® Solution: A Single, Flexible Platform that Delivers Sustained Value

AspenTech Advanced Process Control provides a unified environment for AspenTech’s three industry-leading control formulations within an architecture that provides the ultimate flexibility and usability. The choice of three control formulations provides superior control performance, execution efficiency and exceptional constraint handling to maximise asset utilisation regardless of the control challenges. Major benefits are realised through reduced variability, increased throughput and increased yields of more valuable products.

SUSTAINABILITY

Many APC solutions suffer from degrading benefits. Process changes, equipment aging and changing economic conditions are but a few of the factors that drive the need to maintain controller models.

Case Study: Letšeng Diamond Mine

Using APC to Increase Output and Improve Operations at the Letšeng diamond mine

Learn how 4Sight’s Operational Technologies, Asset Optimisation division was able to design an APC application spanning the primary, secondary and tertiary crushing circuits, as well as the DMS feed. Multivariable Advanced Process Control (APC) solutions, such as Model Predictive Control (MPC) are designed to simultaneously coordinate multiple process units to achieve synergy throughout a processing plant, resulting in stable operation and a steady platform for optimisation.