Offerings

Enhancing Decision Making with Neural Networks

How Neural Networks Redefine Digital Twins

Neural Networks Enhance Digital Twin Technology

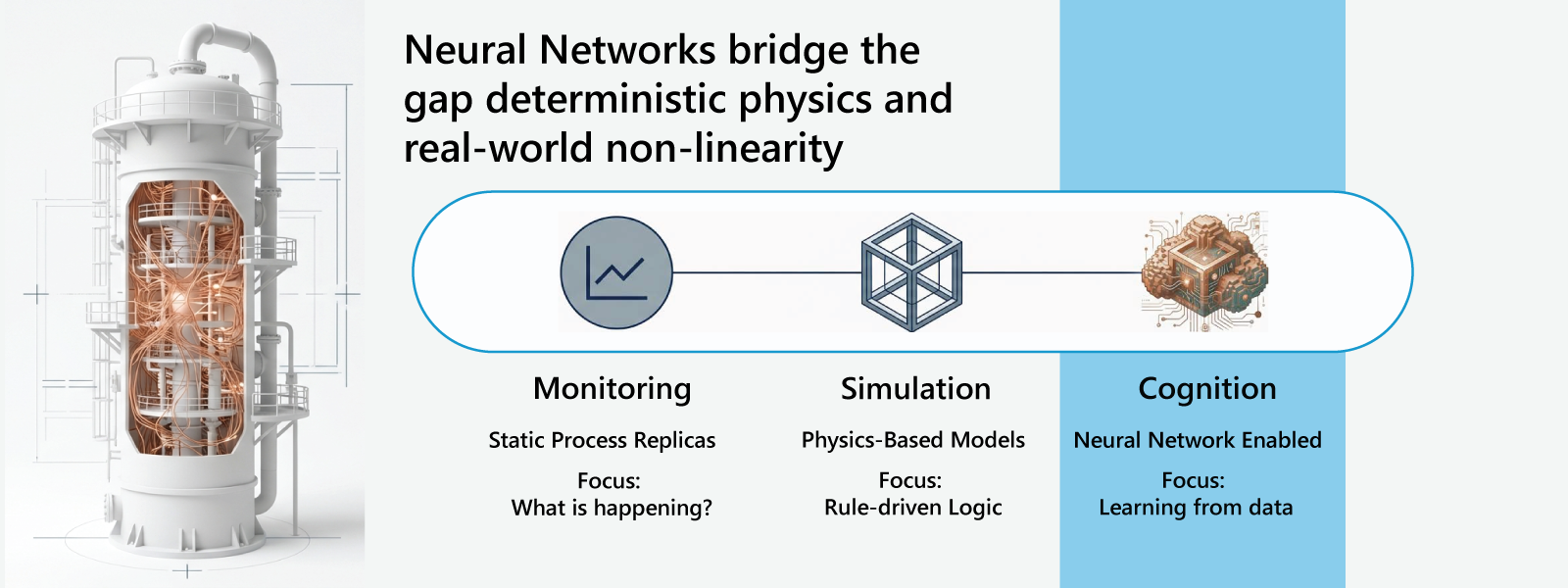

Digital Twins have evolved from static process replicas into intelligent, adaptive systems that continuously learn from operational data. At the core of this evolution are Neural Networks — advanced AI models that enable Digital Twins to move beyond monitoring and simulation, into prediction, optimisation, and autonomous decision support. At 4Sight Operational Technologies, we integrate Neural Networks into Digital Twin architectures to unlock deeper operational insight, improved asset performance, and measurable business outcomes across industrial environments.

From Data Representation to Learning Systems

Traditional Digital Twins rely on physics-based models and rule-driven logic to mirror real-world assets and processes. Neural Networks complement these foundations by learning complex, non-linear relationships directly from operational data — relationships that are often difficult or impossible to model using deterministic equations alone.

By continuously training on live and historical data, Neural Networks allow Digital Twins to:

- Adapt to changing operating conditions

- Recognise patterns hidden in large, high-frequency datasets

- Improve accuracy over time without manual recalibration

The result is a Digital Twin that evolves alongside the operation it represents.

Predictive Intelligence and Early Insight

One of the most powerful applications of Neural Networks within Digital Twins is predictive intelligence. Neural Networks excel at identifying subtle trends and early indicators of future behaviour, enabling Digital Twins to anticipate issues before they occur.

This includes:

- Predicting equipment degradation and failure modes

- Forecasting production performance and throughput constraints

- Anticipating energy consumption and emissions patterns

By embedding this predictive capability, 4Sight’s Digital Twins shift operations from reactive to proactively optimised.

Real-Time Optimisation of Complex Systems

Industrial operations are dynamic, interconnected, and influenced by countless variables. Neural Networks enable Digital Twins to evaluate these variables simultaneously and recommend optimal operating strategies in real time. Through continuous learning, Digital Twins can:

- Identify the most efficient operating setpoints

- Balance production, energy usage, and asset health

- Optimise trade-offs across cost, sustainability, and performance objectives

This creates a decision-support environment where operators and engineers are guided by data-driven intelligence, not static assumptions.

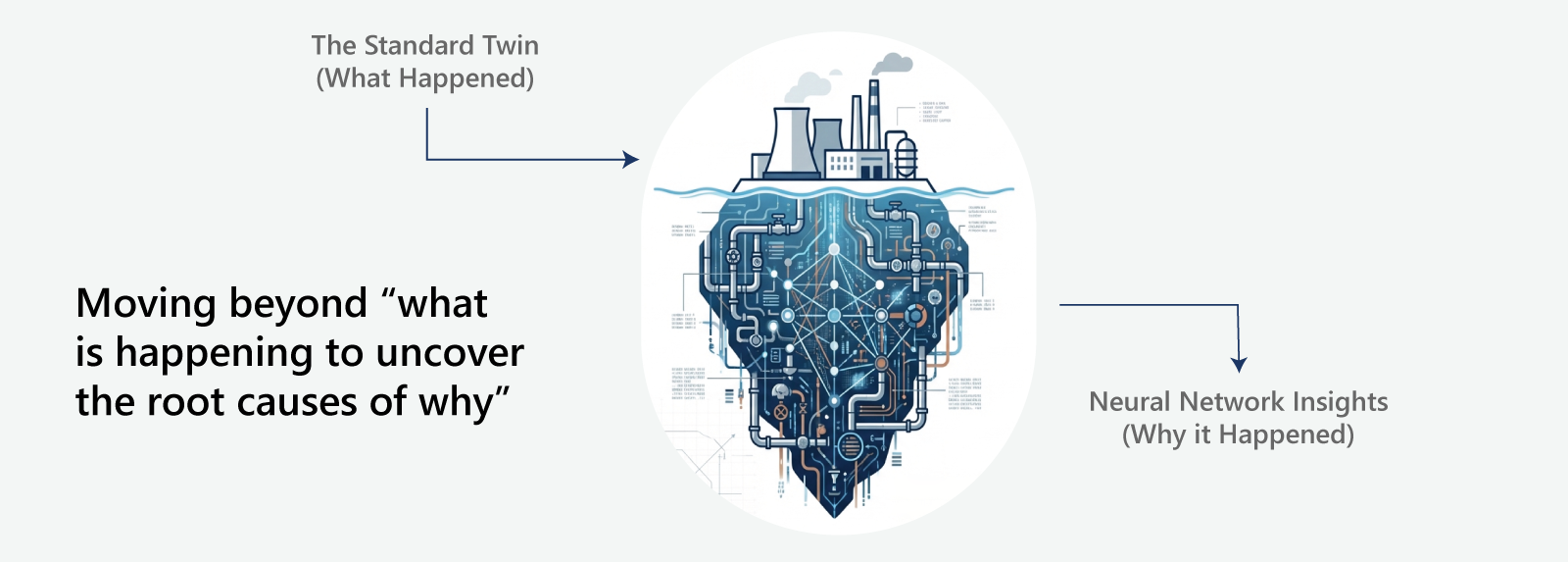

Enhancing Asset and Process Understanding

Neural Networks help Digital Twins move beyond “what is happening” to explain why it is happening. By analysing correlations across process variables, asset behaviour, and environmental conditions, they uncover root causes of inefficiency and instability.

This capability enables:

- Improved process stability and control performance

- Faster diagnosis of abnormal conditions

- Deeper insight into system interactions across the value chain

For complex industrial systems, this level of understanding is critical to achieving sustained operational excellence.

Continuous Learning and Operational Resilience

Unlike traditional models that require periodic redesign, Neural Network-enabled Digital Twins learn continuously. As new data is generated, the Digital Twin refines its predictions and recommendations, remaining accurate even as equipment ages, feed characteristics change, or operating strategies evolve. This continuous learning strengthens:

- Operational resilience in volatile environments

- Confidence in decision-making

- Long-term return on digital investments

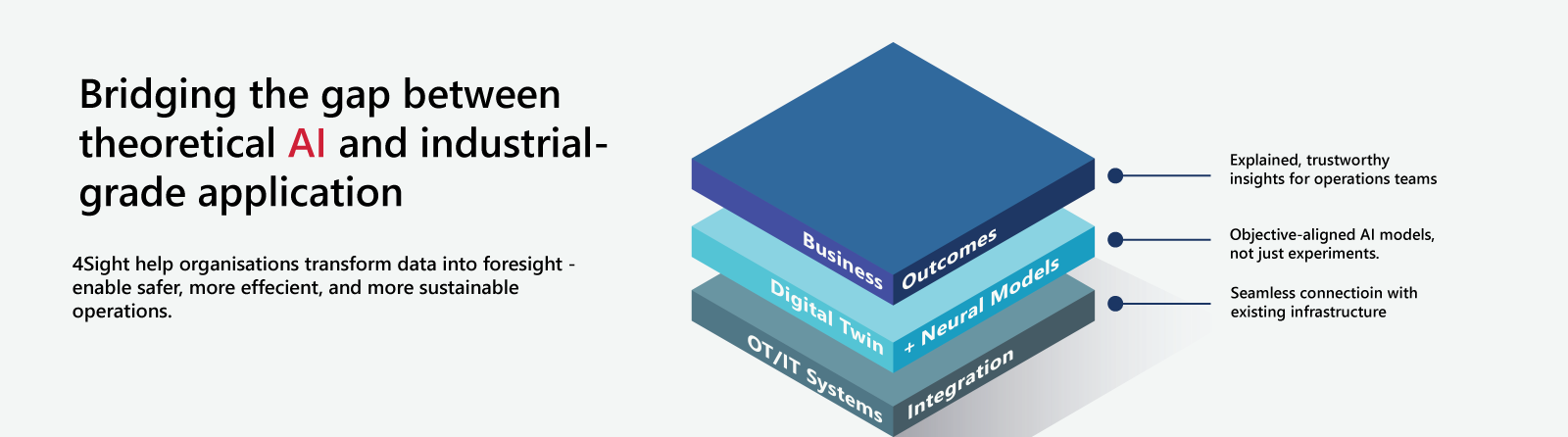

4Sight’s Approach to Neural Network-Enabled Digital Twins

At 4Sight Operational Technologies, we combine deep operational expertise, industrial-grade Digital Twin platforms, and advanced Neural Network models to deliver solutions that are practical, scalable, and value-driven. Our approach ensures that Neural Networks:

- Are aligned to real operational objectives

- Integrate seamlessly with existing OT and IT systems

- Deliver explainable, trustworthy insights to operations teams

By embedding intelligence directly into Digital Twins, 4Sight helps organisations transform data into foresight — enabling safer, more efficient, and more sustainable operations.