Blog

Leveraging AI-Driven Predictive Maintenance in Industrial Simulation

In today’s rapidly evolving industrial landscape, integrating AI-driven predictive maintenance within industrial simulation is not just a trend but a necessity. By leveraging advanced technologies, businesses can anticipate maintenance needs, reduce downtime, and optimise operations. At 4 Sight OT, we are at the forefront of this technological revolution, offering cutting-edge solutions to help industries harness the power of AI for predictive maintenance.

Predictive maintenance involves using AI algorithms to analyse data from various sensors and systems within industrial equipment. This analysis predicts when a component will likely fail or require maintenance, allowing for timely interventions. Unlike traditional reactive maintenance, which responds to equipment failures after they occur, or preventive maintenance, which is scheduled based on average lifespans, predictive maintenance is dynamic and data-driven. It focuses on the actual equipment condition, leading to more efficient maintenance schedules and cost savings.

Benefits of AI-Driven Predictive Maintenance

Reduced Downtime: One of the most significant advantages is reducing unexpected equipment failures. By predicting when maintenance is needed, operations can be scheduled during planned downtime, minimising disruption to production.

Cost Savings: Predictive maintenance reduces unnecessary maintenance activities and prevents costly emergency repairs. It also extends the life of equipment by ensuring that parts are serviced only when needed, avoiding over-maintenance.

Improved Safety: By identifying potential failures before they happen, predictive maintenance enhances workplace safety. It ensures that equipment operates within safe parameters, reducing the risk of accidents.

Enhanced Efficiency: AI-driven predictive maintenance optimises the use of resources. Maintenance teams can focus on critical tasks rather than routine inspections, improving overall operational efficiency.

Integration with Industrial Simulation

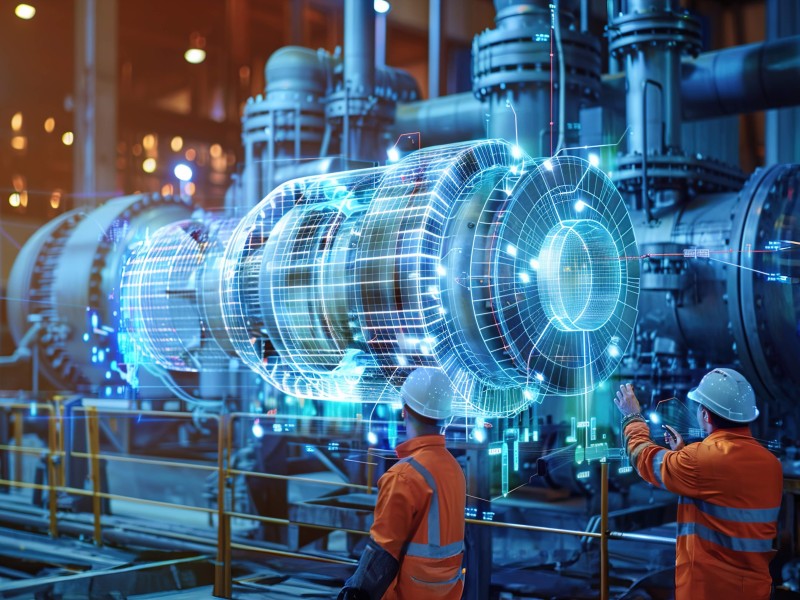

Integrating AI-driven predictive maintenance with industrial simulation provides a powerful tool for businesses. Simulation models can create digital twins of industrial processes, enabling a detailed analysis of how equipment and systems perform under various conditions. By incorporating predictive maintenance into these models, businesses can test different scenarios, plan maintenance schedules more effectively, and foresee potential issues before they arise.

At 4 Sight OT, we utilise sophisticated simulation tools combined with AI to deliver bespoke solutions tailored to our customers’ needs. Our approach involves creating accurate digital replicas of industrial environments where predictive maintenance strategies can be developed and refined. This integration allows continuous improvement, ensuring our customers remain ahead of the curve in an increasingly competitive market.

The convergence of AI-driven predictive maintenance and industrial simulation represents

a significant advancement in industrial operations. By adopting these technologies, businesses can achieve unparalleled efficiency, safety, and cost-effectiveness.