Case Studies

Making Accurate Future Decisions for a Stockpile and Train Loading Facility

Our Client’s Challenge

The projects department at our client needed to investigate a train loading facility which utilised a combination of front-end loaders and haul trucks as an alternative to their existing reclaimer load-out station. This involved the movement of material from the gantries via haulers loaded by front-end loaders all the way to a secondary stockpile. The objective of the model was to determine the stockpile reclaim rates for various operating conditions and equipment configurations.

Scope of Services

We developed a computer simulation model of the proposed surface stockpiling, hauling and rail load-out operations. It included all the rail wagons that were to be loaded near the secondary stockpile with the use of front-end loaders. The model quantifies the equipment interference that can be expected based on surface space constraints and the specifications of the proposed ore handling equipment.

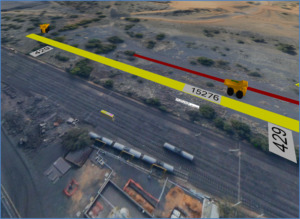

Overview of the facility.

Project Highlights

The project provided our client with a platform to evaluate future throughput scenarios and the impact of what the change in workload will have on the operations. The client was able to accurately determine the equipment configurations and operational requirements for the various options evaluated. They were also able to determine the required rail demand in terms of loading time, loading capacity, train lengths, train arrivals (slots) and yard/facility capacity. The optimal scenario supplied the rail load-out silos at a maximum rate to reduce rail car loading time.