Blog - Operational Technologies

Combining Discrete Event Simulation and AI - Enhance Decision-Making

In today’s rapidly evolving industrial landscape, businesses constantly seek innovative ways to optimise operations, increase efficiency, and reduce costs. Two transformative technologies that are playing a pivotal role in this optimisation journey are Discrete Event Simulation (DES) and Artificial Intelligence (AI). These technologies create a powerful synergy, driving digital twin solutions like Process Digital Twins to deliver highly optimised and intelligent solutions to complex operational challenges.

The Power of Discrete Event Simulation

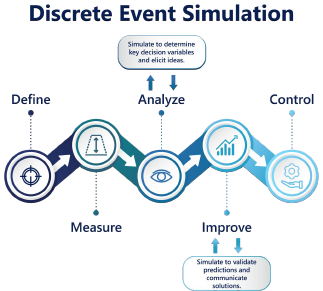

Discrete Event Simulation (DES) has long been a foundational tool for industries looking to model, simulate, and analyse processes. It enables companies to break down complex operations into individual events and activities, helping them understand and predict how processes will behave in different scenarios. DES provides visibility into process bottlenecks, resource allocation, and throughput, allowing for data-driven decision-making.

However, while DES offers exceptional insight into system behaviour, it traditionally requires significant manual intervention to adjust variables and test different scenarios. This is where the synergy with AI becomes game-changing.

AI: Adding Intelligence and Speed to the Simulation Process

Artificial Intelligence, particularly machine learning algorithms, can process vast amounts of data in real-time, learning from historical and simulated data to uncover patterns and trends that humans may overlook. When integrated with DES, AI can enhance the predictive capabilities of simulations by constantly learning from new inputs and optimising outcomes based on real-time data.

For example, in a production facility, AI can learn from both the simulated and real-world operational data to fine-tune resource allocation, predict equipment failures, and suggest process improvements, all while adapting dynamically to changing conditions. This eliminates the need for manual adjustments, making the simulation faster and more accurate.

Process Digital Twins: The Best of Both Worlds

Process Digital Twins are revolutionising the way industries approach process optimisation. Combining DES’s event-driven accuracy with AI’s predictive Intelligence, these digital twins can solve complex operational problems with unprecedented speed and efficiency. Digital twins are virtual replicas of physical systems, which means they can simulate and predict the behaviour of real-world processes in real time. By integrating AI into this digital environment, Digital Twins become intelligent entities capable of self-learning, continuously optimising operations as new data streams in.

This results in faster decision-making, as AI-enhanced simulations can run thousands of scenarios in seconds, identifying the most optimal solutions without human intervention. Whether optimising a supply chain, scheduling maintenance activities, or predicting downtime, AI-powered digital twins can uncover solutions that save time, reduce costs, and minimise risks.

Benefits of the Synergy Between DES and AI

The combination of Discrete Event Simulation and AI creates several tangible benefits for organisations:

- Accelerated Problem Solving: AI’s ability to process data and run simulations quickly means that solutions to complex operational challenges can be generated in a fraction of the time it would take using traditional methods.

- Dynamic Optimisation: Unlike static simulations, AI-powered digital twins constantly learn and adjust in real-time, ensuring that operations remain optimised even as variables change.

- Cost Reduction: By automating the process of finding the most efficient solutions, AI helps businesses save on costs related to resource allocation, downtime, and inefficient processes.

- Increased Accuracy: AI’s predictive capabilities mean simulations can anticipate and account for a broader range of variables, leading to more accurate predictions and outcomes.

- Enhanced Decision-Making: Businesses can make more informed decisions with the insight provided by AI-driven simulations, allowing them to address potential issues before they impact operations proactively.

Real-world Applications

Across industries such as manufacturing, logistics, mining, and healthcare, the combination of Discrete Event Simulation and AI is already proving to be a game-changer. In mining operations, for example, AI-powered digital twins can simulate the entire mining value chain, from extraction to logistics, allowing operators to optimise each process step while minimising environmental impact.

In manufacturing, these digital twins can simulate production lines, identifying inefficiencies and suggesting improvements that reduce waste and increase throughput. The applications are virtually limitless, and as AI technology continues to evolve, the potential for DES and AI to revolutionise industries will only grow.

Conclusion: The Future of Process Optimisation

Integrating Discrete Event Simulation and Artificial Intelligence unlocks new possibilities for process optimisation. With tools like Process Digital Twins at the forefront, businesses can now harness the full power of AI to generate solutions that are not only highly optimised but also delivered with lightning-fast efficiency.

In an era where agility, efficiency, and data-driven decisions are paramount, this powerful combination is set to become the gold standard for solving complex operational problems. To learn more about how your business can benefit from AI-driven simulations, contact our team today and start transforming your operations for the future.

Discover how Process Digital Twin technology can deliver optimised, intelligent solutions tailored to your business needs. Contact Jaco Botha today to explore the future of process optimisation.