Blog - Operational Technologies

Simulation has shifted from a Nice-to-have Tool to a Must-have Technology for the Mining Industry

The evolution of simulation in mining

Historically, mining operations relied heavily on experience, intuition, and essential decision-making tools. While these methods were sufficient in the past, the growing complexity of mining projects and the increasing pressure to optimise resources necessitated a more scientific approach. This is where the simulation entered the scene.

Initially, simulation was perceived as a luxury—an advanced tool used by only the most forward-thinking companies. Its primary use was planning and testing different scenarios without interrupting actual operations. However, as the technology matured, its capabilities expanded, and its value became undeniable. What was once a

“nice-to-have” has evolved into a “must-have” technology for staying competitive in the modern mining landscape.

Why Simulation is now a must-have

Enhancing operational efficiency must-have

The mining industry is under constant pressure to optimise operations and reduce costs. Simulation allows companies to model their entire operation, from drilling and blasting to hauling and processing, and identify inefficiencies that would otherwise go unnoticed. By testing various scenarios and adjusting in a virtual environment, mines can significantly improve their processes and avoid costly mistakes.

Improving safety and risk management

Safety is paramount in mining, where hazardous conditions are a daily reality. Simulation technology enables mining companies to anticipate and mitigate risks by visualising potential hazards and testing emergency response plans in a controlled, risk-free environment. This proactive approach to safety protects workers and reduces the likelihood of operational disruptions caused by accidents.

Supporting environmental sustainability

With the growing emphasis on Environmental, Social, and Governance (ESG) standards, mining companies are increasingly focused on minimising their environmental impact. Simulation plays a crucial role in this effort by allowing companies to optimise resource use, reduce waste, and model the environmental consequences of their activities. By doing so, mines can make more informed decisions that align with their sustainability goals.

Facilitating digital transformation

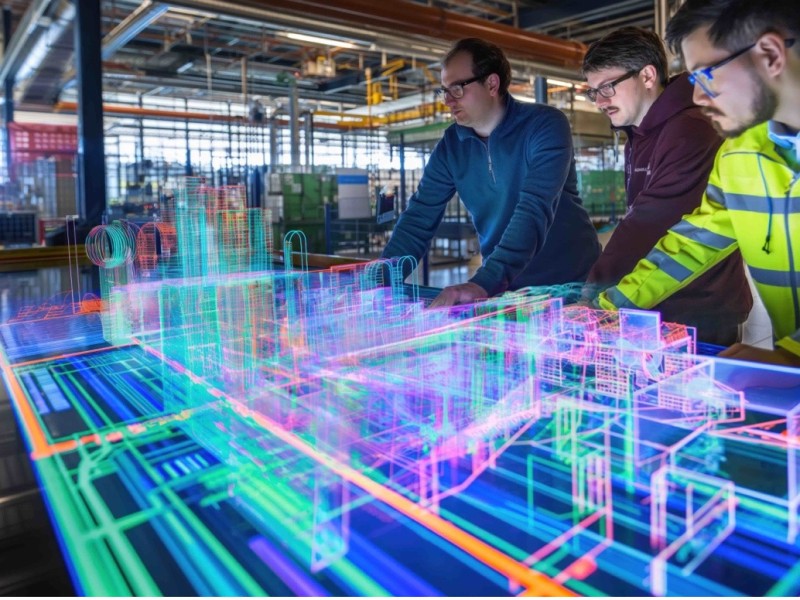

The digital transformation of the mining industry is well underway, with technologies like AI, IoT, and big data analytics leading the charge. Simulation is at the heart of this transformation, acting as a bridge between data and decision-making. By integrating simulation with real-time data from sensors and other sources, mining companies can create digital twins of their operations—virtual replicas that enable continuous monitoring, analysis, and optimisation.

Adapting to market volatility

The mining industry is notoriously cyclical, fluctuating commodity prices and demand levels. Simulation provides

the agility needed to navigate these uncertainties by enabling companies to quickly adapt their strategies to changing market conditions. Whether adjusting production levels, optimising supply chains, or exploring new markets, simulation offers the flexibility required to stay competitive in a volatile industry.

The Future of Simulation in Mining

Simulation will only become more integral as the mining industry continues to evolve. Advances

in computing power, machine learning, and data integration are set to unlock even more significant potential for simulation, allowing for more accurate predictions, real-time adjustments, and holistic operational management.

At 4Sight OT Simulation, we are at the forefront of this technological revolution, helping mining companies harness the power of simulation to achieve operational excellence. Our expertise in simulation technology and our deep understanding of the mining industry position us as a trusted partner for companies looking to transform their operations and future-proof their business.