Case Studies - Operational Technologies

Case Study: Simulation-Driven Insights for Strategic Plant Upgrades

CUSTOMER SUMMARY

Anglo American Platinum requested a dynamic simulation of the Mogalakwena North Concentrator in order to review plant design changes required for the proposed upgrades. The upgrades under investigation were:

• Asset Review Improvement Project (ARIP)

• Low Capex

• Debottlenecking Project (DBP)

The primary objective of the study was to analyse the production capability of the Mogalakwena North Concentrator for each operational scenario by identifying bottlenecks within the system.

CHALLENGES

This project received considerable pushback from management because the suggested design could achieve the same throughput as the existing design but at a lower capex contribution.

SOLUTION

4Sight OT Simulation developed a detailed plant model in the latest Simio® Software version to allow for 3D animation of the processing operations. The model included:

• Conveyors

• Grizzly

• Feeders

• Screen splits

• Crushers

• Primary Mill

• Bins, Silos, and Stockpiles

The model tested the following scenarios to establish the best update solution:

• Current plant operations as the base case

• Asset Review Improvements Project (ARIP)

• Wet Plant Upgrade

• Wet Plant Upgrade with finer blasting

• De-bottlenecking Project (DBP)

BENEFITS AND OUTCOME

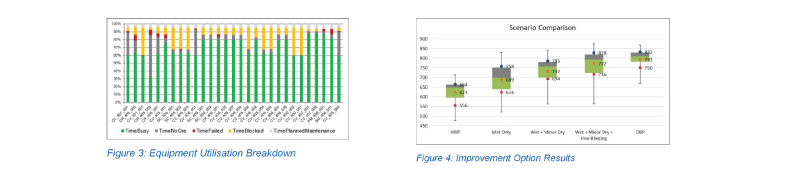

The results of the simulation model aided the client in making an informed decision on the large capital investment in the unstable South African Mining environment. The study identified key areas of concern and the simulation model was used as a platform to compare to the compare the results of the different upgrade options.

The model also enabled the client to experiment with multiple improvement options until the key objectives were addressed. The image below displays the throughput comparisons for the different scenarios.

Critical recommendations were made to assist the client in their decision making with regards to the upgrade option to implement. The simulation model indicated that the de-bottlenecking project will deliver the highest throughput but at the highest capital investment. The most feasible solution in terms of throughput and capital investment was to implement the Low Capex option. This option only sacrificed 8% on plant throughput and resulted in a multi-million dollar saving.