Offerings

Economic and Sustainability Excellence for the Oil & Gas Industry

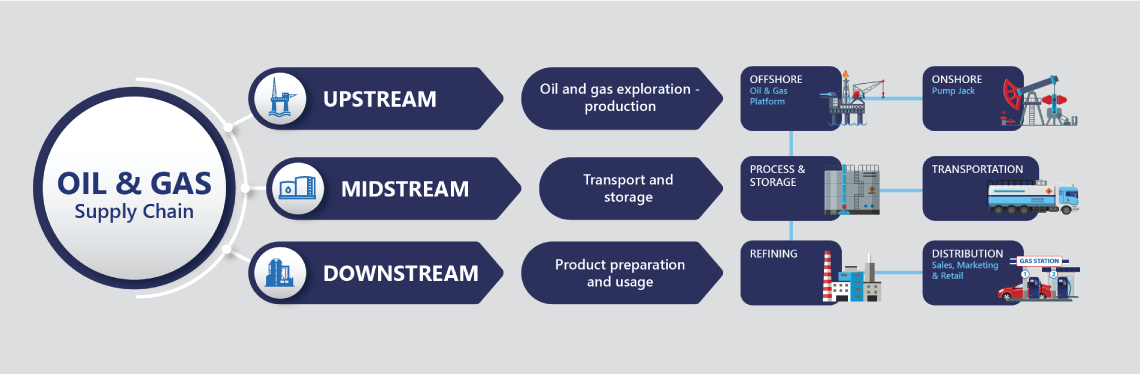

The energy industry is a diverse complex of entities that discover, produce, transport, process, refine and manufacture many products we depend on in our everyday lives.

BUILDING RESILIENCY AND SUSTAINABILITY FOR COMPETITIVE SUCCESS - IN THE LOW CARBON ENERGY ERA

As industry leaders, we recognise the challenges you face and are poised to deliver a comprehensive, adaptable portfolio that caters to all your needs throughout the lifecycle. Our commitment extends to assisting companies in the oil and gas sector as they navigate the shift towards a sustainable future. At the heart of our interconnected products, you’ll find cloud-based solutions built with the utmost cybersecurity standards. Digitalisation in the oil and gas industry empowers equipment like process instrumentation, gas analysers, and motors to seamlessly exchange data, enhancing plant transparency and providing valuable insights for operators to make informed decisions. Increased control translates to heightened safety and efficiency. Amidst a fiercely competitive market, our solutions are scalable, ranging from single plant sections to expansive petrochemical complexes. This scalability ensures you gain a competitive edge, fully capitalising on the potential of digitalisation.

THE FUTURE IS DIGITAL

The global oil and gas sector is witnessing a change like never before. Challenges faced by the oil and gas industry called for a worldwide change. The sector must build on optimising business performance to create new capabilities. And for these two, the business models need a solid digital foundation. The oil and gas sector leaders are automating the oil and gas operations using artificial intelligence and machine learning. The digital strategy is focused on reducing costs and increasing the sector’s efficiency.

Chemical, Oil & Gas industries are facing unique and unprecedented challenges, including profitability, safety, and the increasing demand for environmental, social, and governance (ESG) standards. At 4Sight Holdings, we understand the importance of meeting these challenges head-on and are here to provide the solutions that leading Oil & Gas organisations need. We provide innovative and comprehensive technology-driven solutions to increase efficiency, reduce costs, and improve safety and reporting. Our advanced data-driven approach enables our clients to make better-informed decisions, resulting in increased profits and improved ESG performance. By partnering with 4Sight, you can access a global network of automation experts and process management capabilities to help you IMPROVE OPERATIONS, MAXIMISE MARGINS, and LOWER CARBON EMISSION while making the most efficient use of your resources.

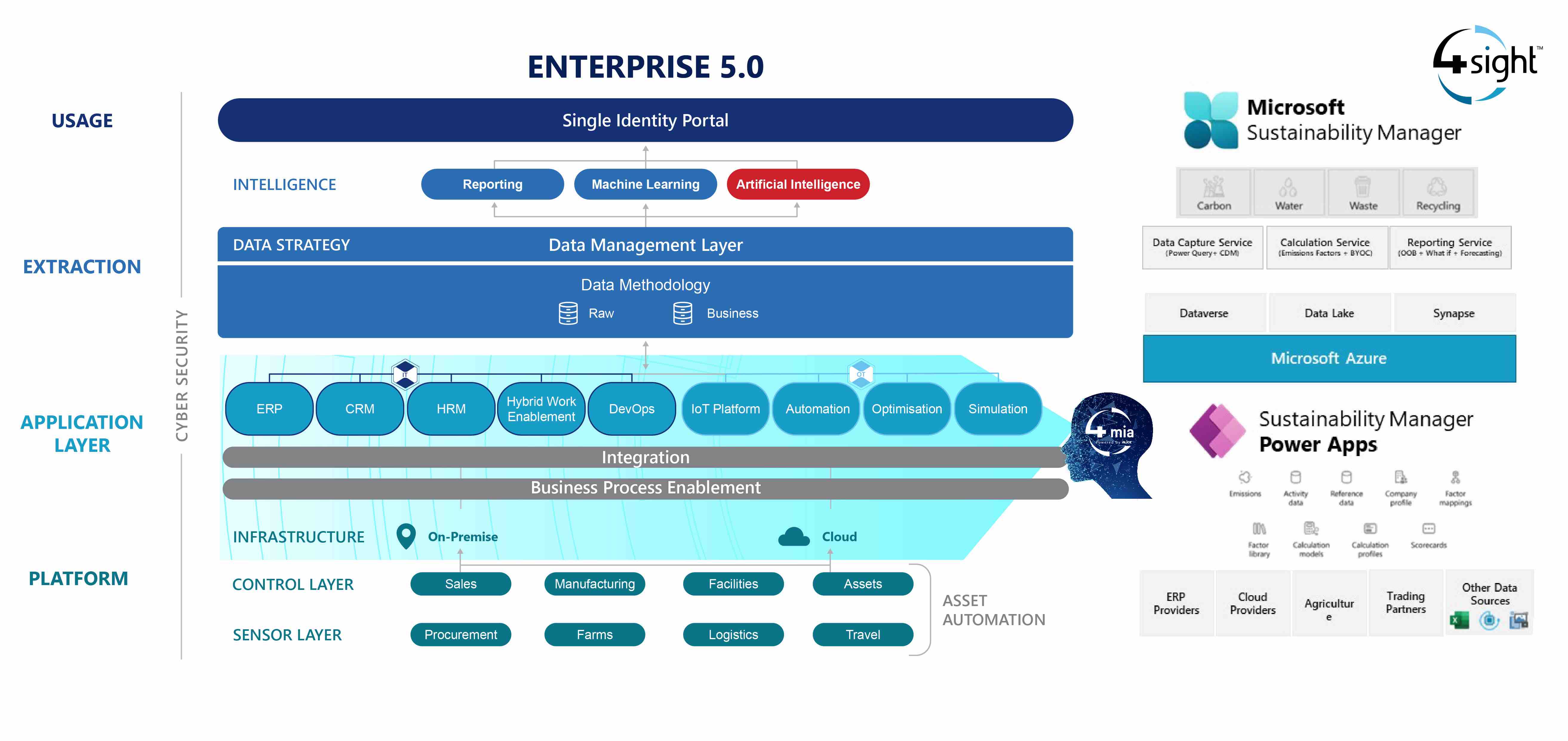

4Sight manage, connect and deliver data analytics from Operational Technologies (OT) and Information Technologies (IT) across the entire enterprise, from intelligent field devices to the edge and the cloud.

Design & Smart Automation

4Sight Holding is a world-leading provider of innovative engineering solutions for the oil and gas industry. Our engineers are dedicated to enabling intelligent automation and improving performance engineering through a centralised, cloud-based, data-centric environment. Our real-time engineering data platform covers the entire lifecycle of a project, from the conceptual design phase through front-end engineering and design (FEED) and detailed design. We strive to provide our clients with the tools and insights necessary to make informed decisions and optimise the performance of their projects.

Manufacturing, Supply Chain and Processing

We are dedicated to transforming your gas processing operations to achieve improved performance and optimize throughput. Our experts and advanced solutions can help you manage operational risks, reduce downtime, and increase plant performance – all while keeping your costs low. We provide state-of-the-art Machine Execution Systems (MES) and Advanced Process Control (APC) technologies to ensure reliable and safe operations. In addition, our solutions will help you identify and address any challenges you may be facing and optimise performance to meet your specific needs. With our expertise and technological capabilities, you can rest assured that your gas processing operations will run efficiently.

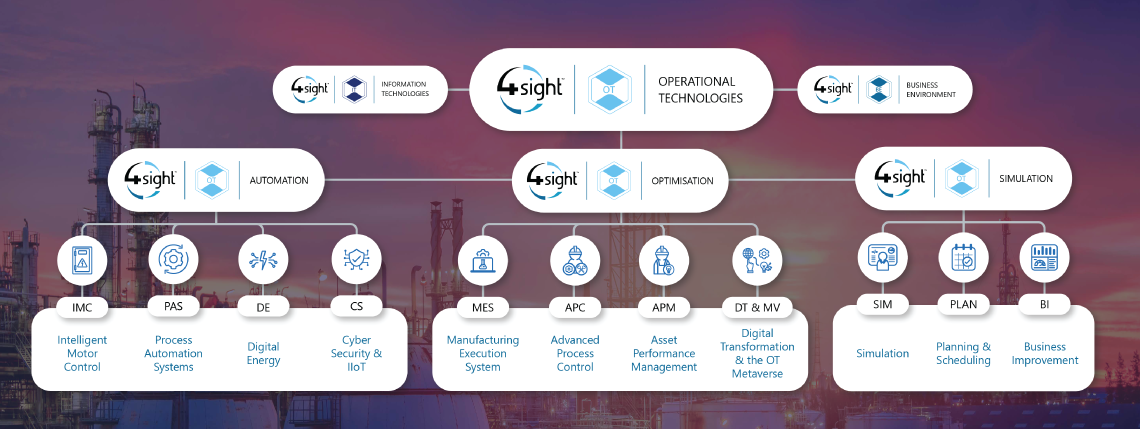

4SIGHT OIL & GAS SOLUTION STRUCTURE - Comprehensive portfolio for digital transformation

Embarking on a journey of digital transformation holds the potential for enhanced operational efficiency, increased plant availability, and heightened flexibility in managing assets and resources. However, realising the full spectrum of benefits from digitalisation in the oil and gas industry requires a steadfast partner. We stand ready to accompany you throughout your transformational endeavours, providing avant-garde, interconnected, and sustainable solutions tailored to electrification, automation, and digitalisation.

The energy industry is a diverse complex of entities that discover, produce, transport, process, refine and manufacture many products we depend on in our everyday lives. Our expert engineering staff helps simplify that complex energy and oil and gas industry to improve operational excellence for your business.

UPSTREAM

UPSTREAM

The Digital Oilfield

Employ fewer, centralised teams of knowledge workers to make better and more insightful use of asset production data. Drive down the break-even cost of production and improve asset yields and efficiency using AspenTech's suite of Asset Performance Management software.

Reliability and Operational Integrity

Apply machine learning and analytics, combined with domain models representing decades of knowledge, to move from reactive to prescriptive asset maintenance and optimisation using AspenTech's proven tools and software for Asset Performance Management.

Standardised Designs

Employ standardised designed templates and a closed-loop workflow to move away from one-of-a-kind designs to standardised designs. Reduce cost and design risk, speed up and de-risk capital decision-making, and reduce CAPEX — all using AspenTech's Performance Engineering for CAPEX approach.

MIDSTREAM

MIDSTREAM

Improve Midstream Reliability, Operability and Availability

Predict and avoid equipment and process upsets and failures for significant improvement in uptime, sale gas quality and quantity, and OPEX.

Reduce CAPEX Cost and Time for Bringing Assets Online

Apply machine learning and analytics, combined with domain models representing decades of knowledge, to move from reactive to prescriptive asset maintenance and optimisation using AspenTech's proven tools and software for Asset Performance Management.

Shrink the Hydrocarbon Value Chain

Employ standardised designed templates and a closed-loop workflow to move away from one-of-a-kind designs to standardised designs. Reduce cost and design risk, speed up and de-risk capital decision-making, and reduce CAPEX — all using AspenTech's Performance Engineering for CAPEX approach.

DOWNSTREAM

DOWNSTREAM

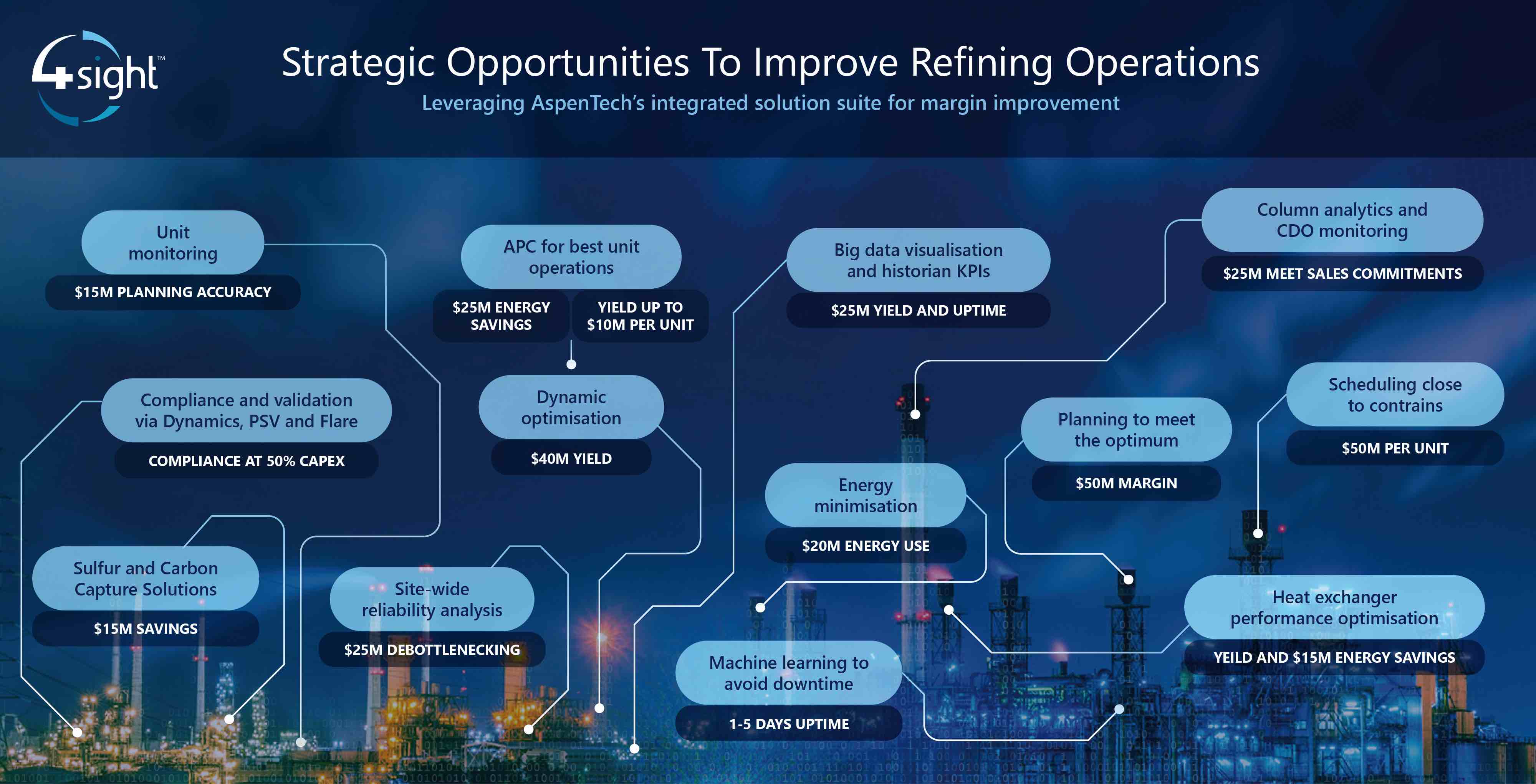

Capture the Margin Gap

Capture the margin gap in your refinery by tying together planning, scheduling and advanced control with the "glue" of dynamic optimisation using AspenTech's software to drive and maintain Unified Production Optimisation. Optimise key areas in your plant, such as middle distillates, residuals conversion, hydrogen plants and contaminants capture.

Reliability and Operational Integrity

Rapidly evaluate debottle-necking, expansion, and product alternatives with advanced modeling tools and enterprise risk analysis. Achieve maximum refinery flexibility in the face of macroeconomic uncertainty using AspenTech's Performance Engineering for OPEX approach.

Refinery Digital Transformation and Reliability

Building on the base of key enabling technologies such as adaptive process control, online performance monitoring and refinery planning, enhance reliability, uptime, asset utilisation and sustainability using AspenTech's approach to Asset Performance Management.