Offerings

Integrated Metal Accounting Solutions

Increase the reliability and validity of your metal accounting data throughout the value chain.

Operations Reconciliation and Accounting expertise enable timely completion of plant boundary and unit balances. Produce daily reports of plant inventory and overall production numbers to enable better business decisions.

Metal inventories are reported in the financial statements of mining companies. Many mining companies are unable to validate the accuracy of metals in inventories at the end of their financial year. This has an adverse impact on metallurgical accounting and metal valuation. Reliable metal accounting has become essential for sound corporate governance.

The 4Sight Asset Optimisation Metal Accounting solution addresses this problem by providing valuable information about plant operations to operational management like recovery rates, plant mass balance and potential areas of material losses and most importantly, real-time visibility of Metal in Process (MIP).

Real-time information allows for better decision making and more accurate reporting. Integration of this solution into the ERP system allows for accurate, real-time, financial and metal accounting.

Optimising your metallurgical processing operation throughout the value chain.

ENTERPRISE OPERATIONS REPORTING

- EOR displays valuable process data to users who can apply it toward improved productivity, increased profits, and enhanced business flexibility.

- EOR collects, manipulates, and stores large volumes of process data and makes this data accessible for analysis and reporting by client users, business systems and production applications.

USER-DEFINABLE DATA MODEL

The system uses a data-driven architecture with a flexible data model that can adapt to the needs of an application. All process segments and characteristics can be defined according to any conceptual model the customer requires in a graphical environment. Each value is configured as to how it should be stored, exactly where it will come from, any calculations that should be performed and how it will be reported.

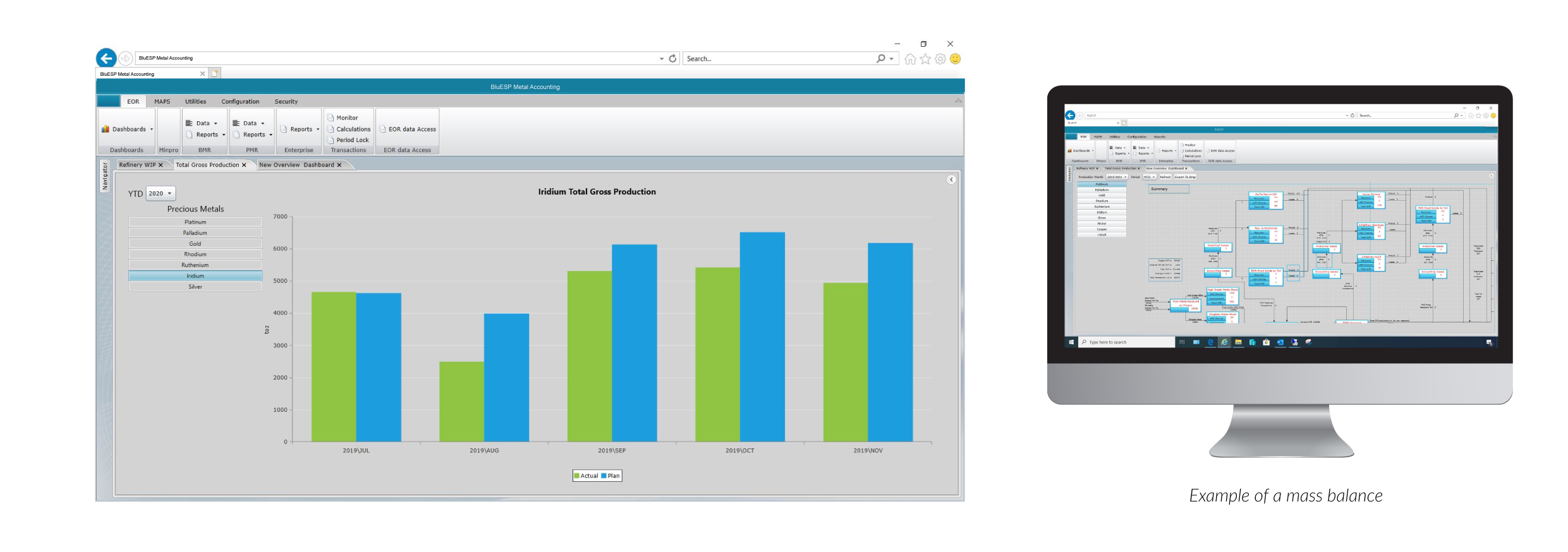

Dashboard Example

SECURITY AND ACCESS

The EOR supports a three-tier security model based on authentication, role, and object. Specifically, this means that a given user, when logging on, has privileges granted on the basis of:

- Who they are (authentication)

- What their business role is (function is)

- What objects (functionality) they need to access

User authentication is based on Active Directory (AD) authentication using a replaceable membership provider. This approach provides a powerful and simple method of exercising control over access to information within the EOR system. A security manager allows the user to create roles, add users or groups to roles and delete roles. Each user or role can then be assigned various functionalities within the system (e.g. To view a report or enter data manually).

REPORTING PERIOD AGGREGATION

Reporting periods are user configurable. These periods can be automatically scheduled to occur at any interval required from a set start date, or they can be manually created for scenarios where the interval varies. Each characteristic is configured separately as to how aggregation of the data should take place (i.e. summed, averaged, or using a custom calculation). The aggregation takes place as soon as the data is received, making reporting fast and easy for whatever period is required.

Example: Data may be received on an event or batch basis. Batches should be summed up for the relevant production month, which runs from say 19:00 on the 21st of one month to 19:00 on the 21st of the next month. Each production month then needs to be summed

up for the production year running from July to June and for the financial year running from January to December.

INFORMATION QUARANTINE

Data is placed in a quarantine for each particular reporting period and process area, until a user with the required security, publishes the data. This makes the data available to other users when it is deemed correct for that particular reporting period.

CONSISTENT DATA STORAGE

All information received by the system is converted to the relevant engineering unit defined for the characteristic before it is stored in the database. This ensures that even when data is received from various interfaces, each with their own representation of the data (for example one system may report values in kilograms and another in tons), the information received will be stored in a predefined unit of measure.

INTERACTIVE DASHBOARDS

Because all data is processed upon receipt of the data, the dashboards are fast, graphical screens to make KPI information available to the users. Each screen utilises role-based security to control what the user may see.

OPERATIONAL AND FINANCIAL BENEFITS INCLUDE:

- Decreased production variability

- Reduced material losses

- Better diagnostic and troubleshooting capabilities for process problems or deficiencies

- Monitoring and tracking process-specific KPIs

- More accurate determination of process efficiency and recovery rates

- Increased accuracy for checking Mine Call Factors

- Enhanced production forecasting capabilities