Offerings

OptiSlot DC

4Sight OT Simulation is a proud representative of the OptiSlot DC™ warehouse optimisation software, developed by Optricity.

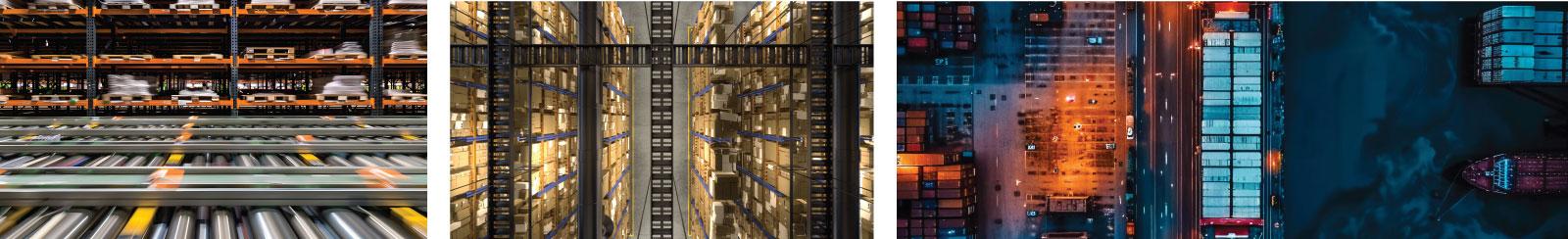

In an environment where customers demand the right product, in the right place, at the right time, distribution centres must work hard to meet and exceed these expectations. An optimally slotted warehouse supports efficient put away, picking, and pallet building; reduces product damage; and increases customer satisfaction.

OptiSlot is a slotting optimisation software designed to enhance the efficiency of warehouse and distribution centre operations. It enables businesses to organise inventory more effectively by employing advanced mathematical algorithms to determine the ideal placement of products within a warehouse. This optimisation considers factors such as product dimensions, weight, velocity, and operational objectives like order fulfilment speed and space utilisation. Primarily utilised in distribution centres, OptiSlot streamlines operations and ensures that warehouse layouts are aligned with business requirements, making it an essential tool for companies aiming to improve supply chain efficiency.

Like most organisations, you may find it difficult to deal with the myriad of slotting issues, which have become too complex for guesswork, paper-based calculations, spreadsheets, and outdated slotting methodologies. Now you can take the guesswork out of your slotting initiatives. By providing rapid and easy to perform multiple “what-if” slotting scenarios, OptiSlot DC™ allows you to compare operational goal achievement and financial return for each scenario. After comparing the results, you can select the optimal slot strategy to execute.

Proper slotting balances, or optimises, the assignment of a pick location for each SKU based on unique product attributes, the physical characteristics of the distribution centre, and the organisation’s operational goals. All of these factors must be balanced to achieve the optimal slotting solution.

OptiSlot DC™ addresses the complexities of slotting by utilising advanced mathematical algorithms which consider a product’s dimensions like weight and velocity, physical characteristics of your environment including slot configurations, pick path and material handling equipment, and operational goals like pallet building, seasonality requirements and retail groupings.

As a result of implementing advanced slotting technology, your operations benefit from reduced labour expenses, improved order fulfilment cycle time, a reduction in partial order shipments, and improved space utilisation.

4Sight OT Simulation boasts extensive knowledge and expertise in OptiSlot DC, underpinned by significant experience in optimising operations within the mining and manufacturing sectors. Our team harnesses the power of OptiSlot DC to enhance warehouse and distribution centre efficiency through advanced slotting and layout optimisation. By applying industry-specific insights and cutting-edge simulation techniques, we empower businesses to streamline their processes, reduce costs, and maximise productivity in their supply chain operations.